Contact Lens Solution: Contact lenses are therapeutic ophthalmic devices meant for use in the eye. Contact lenses are divided into the following types:

1. Rigid, hydrophobic called ‘hard lenses’ made of polymethyl methacrylate (PMMA).

2. Rigid, semihydrophobic.

3. Flexible, hydrophilic called ‘soft lenses’.

4. Flexible, hydrophobic and rigid gas permeable.

Each lens class is accompanied by its support solution products and devices.

1. Hard Contact Lenses:

They provide durability and clear crisp vision to the patient. These are made of a rigid plastic resin PMMA & hence called hard contact lenses. Therefore many people found them extremely uncomfortable to wear and tolerate. These are practically impermeable to O2 and moisture, another disadvantage to corneal epithelial respiration and patient comfort. Care must be taken to prevent the hard lens from resting directly on the corneal surface to protect the epithelial tissue from physical damage. To prevent such direct contact, solutions are used that wet the surface of the lens to provide a cushioning layer between the corneal epithelium and the inner surface of the lens.

Wearers of hard contact lenses generally use two solutions for the routine maintenance program:-

(a) Wetting solution: It is used primarily for treating the lenses before insertion. Due to its hydrophobic nature, polymethyl methacrylate is poorly wetted by the lachrymal fluid of the eye. Hence, the contact lenses require moistening with a wetting agent to make the insertion easy and comfortable. Since the contact lens solutions are required to be used daily for years together, they should be prepared carefully and all the ingredients used should be of good quality.

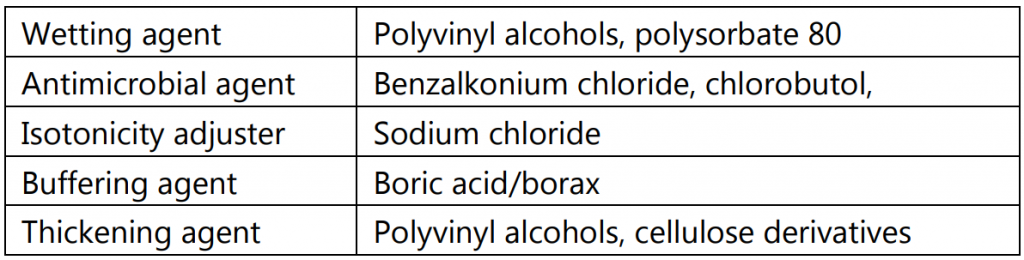

The formulation of contact lens solution

(b) Storage solution: It is used for overnight cleaning, soaking, and storage. The contact lenses after their removal from the eye are cleaned with a wetting solution and rinsed with purified water. Then they are stored in a storage solution to prevent dehydration.

The formulation of the storage solution contains a non-ionic surface active agent which will help in cleaning the contact lenses. It also contains preservatives to prevent microbial growth. The solution should be changed after every few days because the preservatives may be practically inactivated by the organic materials present in the form of debris.

Contact lens solutions should be sterile. The label should warn against contamination during use and encourage frequent changes of storage solution.

2. Soft Contact Lenses:

These are soft flexible type lenses made of a hydrophilic transparent plastic, hydroxyethyl methacrylate (HEMA) that contains 30-80% water. This increased water content of the lens improves its permeability to oxygen. These are of 2 types.

(a) Daily wear lenses: These must be removed at night before sleep.

(b) Extended-wear lenses: These are designed to be worn for more than 24 hours up to 30 days. But it is advised not to leave them in the eye for more than 4-7 days, and remove them for cleaning and disinfection.

Certain medicaments from eye drops and preservatives from wetting and storage solutions are strongly absorbed by the soft contact lenses. Due to this reason, patients wearing soft contact lenses should be advised to remove them before instilling eye drops. For cleaning, soft contact lenses are heated in 0.9% sodium chloride solution. The wetting and storage solution used for hard contact lenses should not be used. Special proprietary storage solutions are available. The wetting of soft contact lenses is not a problem because of the hydrophilic nature of the lens. The storage solution should be sterile.

3. Rigid Gas Permeable Contact Lenses:

They take advantage features of the soft and hard contact lenses. These are constructed of a material that is oxygen permeable but hydrophobic. Thus they permit the transmission of oxygen through the lens more than hard lenses while providing durability and ease of handling like that of hard lenses. These may be either daily wear/extended wear.

Make sure you also check our other amazing Article on : Manufacturing Facilities for Ophthalmic Preparations