Fluid Energy Mill: These are also known as micronized or ultrafine grinders. Method of size reduction: Impact and Attrition

Principle

Table of Contents

Fluid energy mill based on the principle of Impact and Attrition. Size reduction takes place by a high-velocity collision between particles.

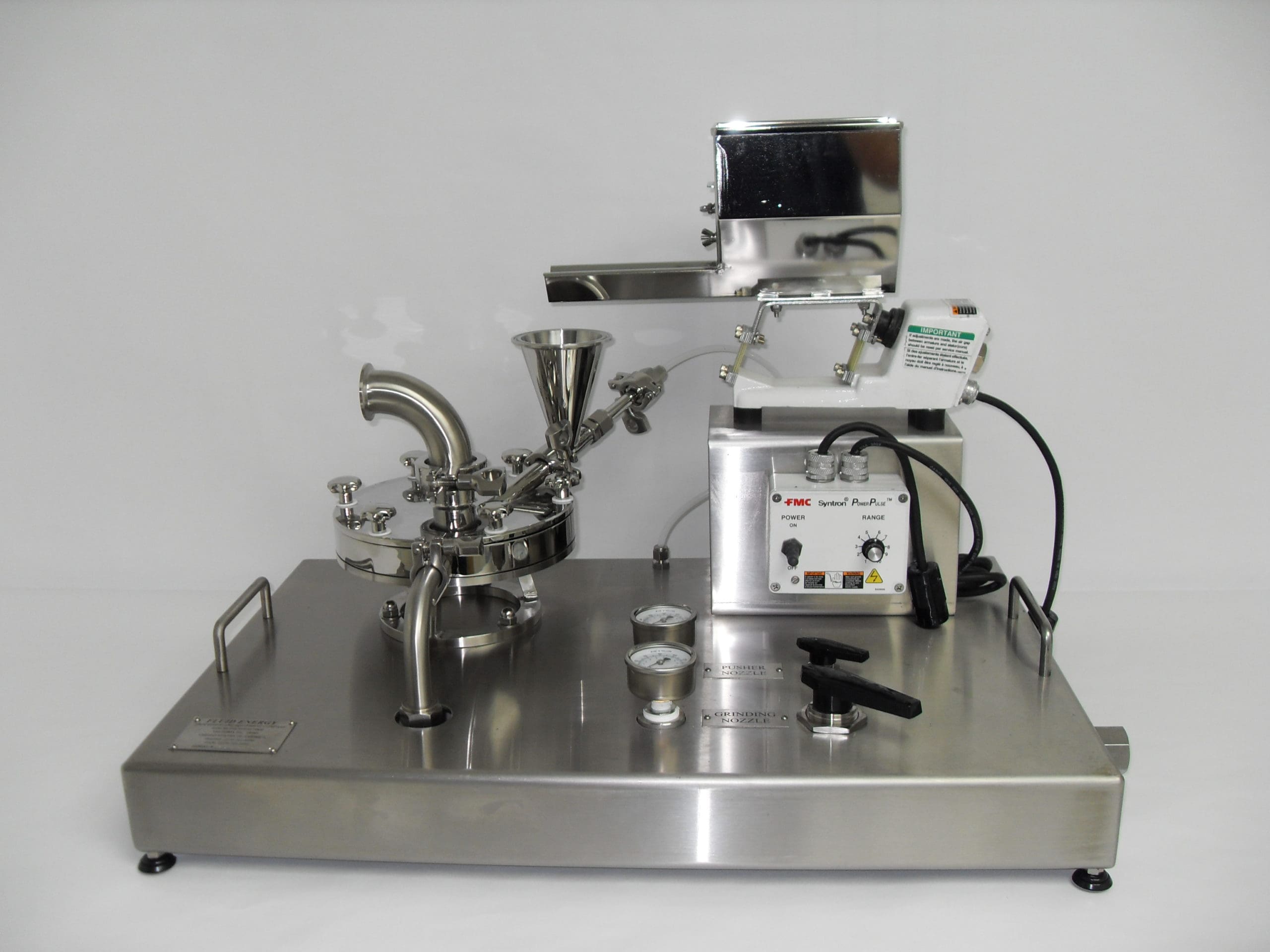

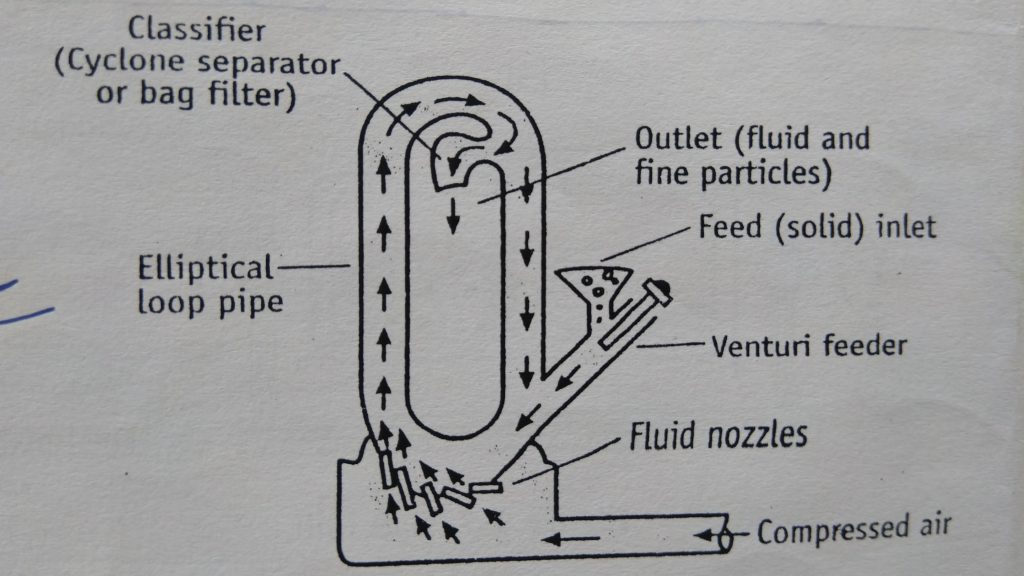

Construction of Fluid Energy Mill

It consists of a loop of pipe, which has a diameter of 20 to 200 mm. The height of the loop may be up to 2m. Several nozzles are fitted at the bottom of the pipe. Generally, 2 to 6 grinding nozzles are present. A classifier is fitted at the product collection point. Normally compressed air is used.

Working of Fluid Energy Mill

The air is injected at very high pressure through nozzles at the bottom of the loop. Compressed air of 600kilopascals to 1.0 megapascals is normally used. This results in a high circulation velocity that produces turbulence. The solids are introduced into the stream through the feed inlet. As a result of the high degree of turbulence, impacts and attrition occur between the particles. A classifier is installed in the system so that only finer-sized particles are collected as products and larger particles are sent back into the air stream for further reduction of size. The feed to the mill is previously of reduced size and passed through a 100-meshes screen. The size of the product may be 5mm or below.

Advantages of Fluid Energy Mill

- This mill is suitable for a thermolabile substance because no heat is produced.

- The particle size of the product is smaller when compared to other methods.

- There is no contamination of the product.

- For oxygen or moisture-sensitive materials, inert gases like nitrogen can be used instead of normal air.

Disadvantages

- Not suitable for soft, and fibrous material milling.

- Expensive.

Application

This method is used where fine powders are required like micronization of griseofulvin (an antifungal drug), antibiotics, etc.

Variant

Centrifugal impact pulverizers: In this equipment, the rotor is pinned to accelerate centrifugal force on particles. As a result, particle moves toward impactors, and on striking final reduction is obtained.

Make sure you also check our other amazing Article on : Working Principle of Ball Mill