Principle

Table of Contents

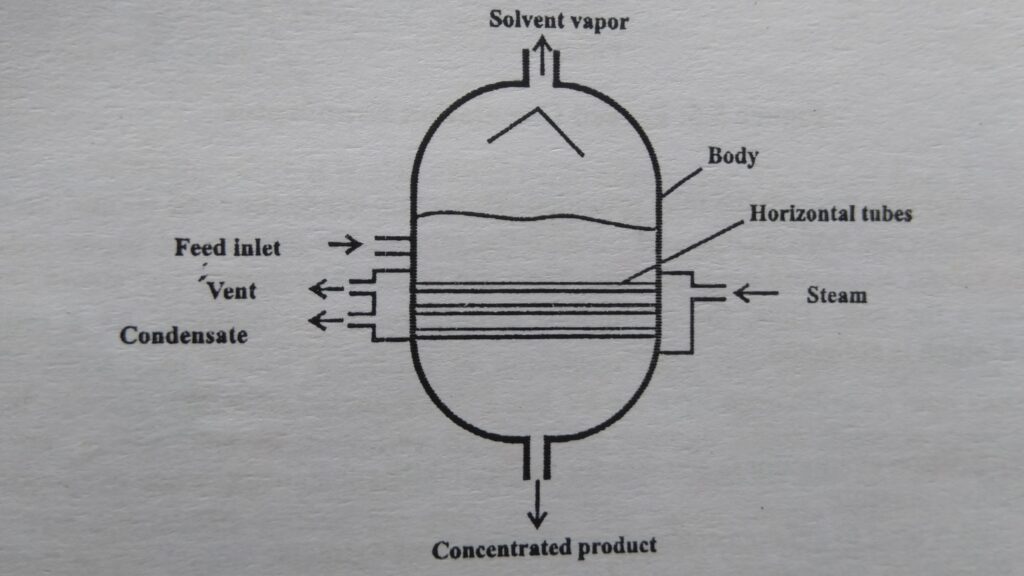

In a Horizontal tube evaporator, the steam is passed through tubes placed horizontally. As a result solvent outside tubes gets evaporated and passed from the top and concentrated liquid is discharged from the bottom.

Construction

It consists of a vertical cylindrical body with a dome-shaped top and bottom part made of cast iron. The lower part of the cylindrical body is fitted to a steam inlet and outlet for condensate. Inside the cylinder horizontal tubes are placed. Horizontal tubes are 6 to 8 in number and made of stainless steel. The lower portion also consists of a vent for noncondensed gases. Feed inlet is also provided. There is one outlet for vapor at the top of the vessel, and the concentrated product is discharged from the bottom of the body.

Working of Horizontal Tube Evaporator

Feed is introduced through the inlet. Steam is also introduced into the body. Therefore tubes get heated. The condensate pass-through outlet. The heat is absorbed by the feed and the solvent gets evaporated. The vapor formed a pass-through outlet at the top of the body. The process repeats to get a concentrated product which is collected from the bottom.

Uses

- A horizontal tube evaporator is used in the pharmaceutical, pulp, and paper industries.

- Also used for making distilled water for boiler feed

Advantages

- Cheap

- Easy to install

- Suitable for a non-viscous liquid that does not crystallize

- Suitable for batch or continuous operation

Disadvantage

- Not suitable for viscous liquid

- They have a smaller capacity than other evaporators

Make sure you also check our other amazing Article on : Steam Jacketed Kettle or Evaporating Pan