ISO 9000

Table of Contents

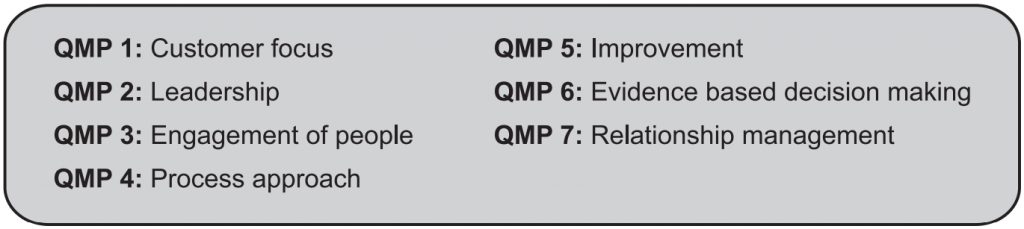

The ISO 9000 family of standards is designed to help organizations to ensure the customers’ needs, the statutory and regulatory requirements. It does not certify any organization. It certifies the QMS of any organization. The basic quality management principles (QMP) of ISO 9000 are:

ISO 9000 Series

ISO 9000: Quality assurance and quality management concepts, guidelines for selection and use.

ISO 9001: Concepts for QA in design, production, and development of the system, along with service and installation.

ISO 9002: Concepts for QA in production, service, and installation.

ISO 9003: Model for QA in final inspection and finished good testing.

ISO 9004: Guidelines for quality assurance and quality management planning, implementation, efficiency, and improvement.

Requirements of ISO 9000 Series

To establish an effective QMS through ISO 9000 series the following points are necessary:

1. Responsibility of the Management of the Organization: The policy to maintain the quality should be ensured by the management of the organization. The quality policy should be implemented and maintained in all the spheres of the organization.

2. Quality System and Design Control: The supplier of raw materials should maintain the quality and documents regarding specifications of the materials. The products should meet predetermined quality and standards.

3. Documentation regarding Stakeholder’s Contract and Purchasing: The well-documented contract review with different suppliers should be maintained by the management. The capability of the contractor should be defined and documented. The details of purchasing and all data should be in documentation and maintained for the record to attain the desired quality management in the organization.

4. Process Control: The design of workflow should be decided, planned, defined, and implemented. The responsibilities should be defined to the personnel for the equipment, process, and change if any in the protocols that should be well documented, reviewed, and proposed for prior approval from the higher and concerned authorities. The production plan, installation, and service should be finalized by keeping in mind that the variations in reaction conditions shall alter the quality of the finished products. The inspection of validation of equipment, calibration process, and efficiency are important concerns.

5. Final Inspection and Testing of Finished Goods: The inspection and analysis for the finished products should be well documented and, the test procedure and result should be reviewed and maintained for the record. The product that does not meet certain specifications should be prevented for further process and installation.

6. Actions taken to Overcome the Errors: The possible causes for the errors should be identified and eliminated. The non-conformities of the products can affect the quality parameters and to maintain the quality management, preventive actions should be taken, reported, and documented. The implementations of the corrective measures should be confirmed.

7. Internal Audits: The effectiveness of the organization and system is determined by the quality of internal audits. The audit report will assure the functioning of the system is adequate or not to maintain the desired quality of the products. The audit report shall be maintained and the corrective steps should be taken by the responsible individual in their respective areas if any deficiencies are found. The audit in regular intervals assures the quality of the process in the organization.

8. Training and Providing Education/Awareness regarding the Standards: The personnel involved in the system shall be provided training, proper education, or workshops about the standards as per requirement. The training report shall be documented and maintained.

9. Statistical Analysis: To analyze and control the process capability, the statistical analysis shall be documented and implemented.

Advantages of ISO Certification

1. Increment in marketability.

2. International recognitions.

3. Reliability in the market.

4. Capability of providing quality products to satisfy the customer.

5. Improvement in relationship with customers and stakeholders.

Make sure you also check our other amazing Article on : Out of Specification