In addition to the DuNouy ring, pendant drop, and number drop methods used for determining surface tension and interfacial tensions, the drop volume method, and the spinning drop method are exclusively used for the measurement of interfacial tension.

Drop Volume Method:

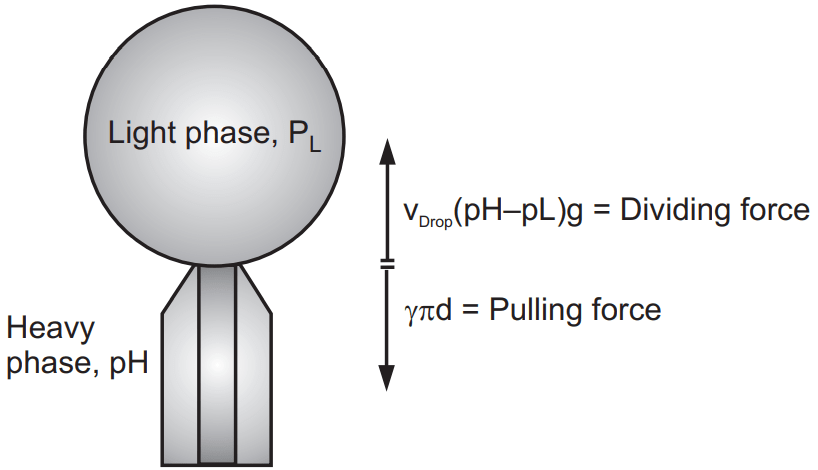

A drop volume tensiometer is an instrument for determining the dynamic interfacial tension. Drops of a liquid are produced in a vertical capillary in a surrounding second liquid. The volume at which the drops detach from the tip of the capillary is measured. The dynamic surface tension can also be measured if measurements are made in the air as the bulk phase. In the drop volume method, a liquid is introduced into a bulk phase through a capillary. A drop, which tries to move upwards due to buoyancy, forms at the tip of the capillary. The reverse arrangement, in which drops of the heavy phase drop from the tip of the capillary, is also possible.

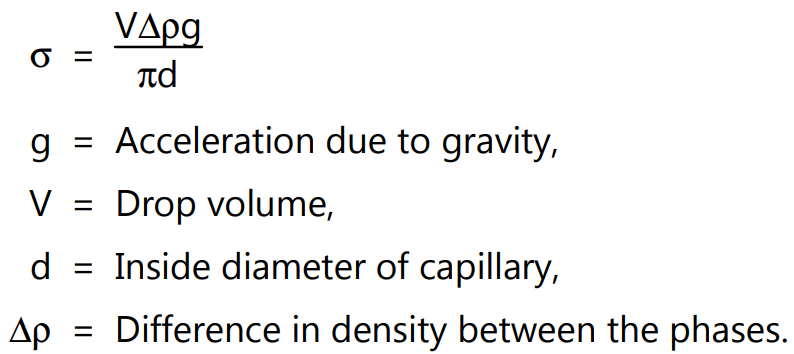

Because of the interfacial tension (γ), the drop tries to keep the interface with the bulk phase as small as possible. As a new interface comes into being when the drop detaches from the capillary outlet, it is necessary to overcome the corresponding interfacial tension. The drop does not detach until the lifting force or weight compensates for the force resulting from the interfacial tension on the wetted length of the capillary, the circumference. The formula for this relationship is:

Spinning Drop Method:

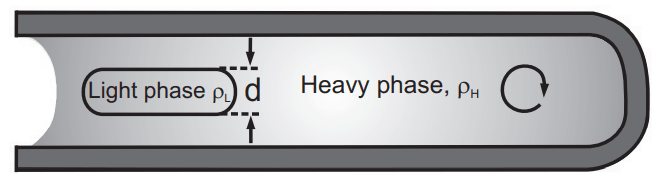

A spinning drop tensiometer is an instrument for the measurement of interfacial tension. Here, a horizontally arranged capillary filled with a bulk phase and a specifically lighter drop phase is set in rotation. The diameter of the drop which is elongated by centrifugal force correlates with the interfacial tension.

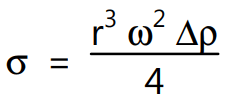

When a heavy bulk phase and a light drop phase are situated in a horizontal, rotating capillary, the drop radius perpendicular to the axis of rotation depends on the interfacial tension γ between the phases, the angular frequency ω of the rotation, and the density difference ∆ρ. Thus, with a given speed of rotation and with known densities of the two phases, the interfacial tension can be calculated from the measured drop diameter d (= 2r) by Vonnegut’s equation:

The drop diameter is determined from the video image of the drop using drop shape analysis. The length of the drop along the axis of rotation must be at least four times the diameter of the drop to minimize the error due to the curvature of the interface. Extremely low interfacial tensions can be measured with a spinning drop tensiometer. The spinning drop method is frequently used when the conditions for forming a micro-emulsion are to be investigated, e.g. with surfactant flooding in enhanced oil recovery (EOR) or in solvent-free degreasing.

Comparison of Methods:

Of the several methods that exist for surface and interfacial tension determinations, there is no method available which suits all types of systems. The choice depends on accuracy, sample size, whether surface or interfacial tension, or the effect of time on surface tension is to be determined.

Make sure you also check our other amazing Article on : Surface Free Energy