Ribbon Blender: The mechanism of mixing is shear which is transferred by moving blades.

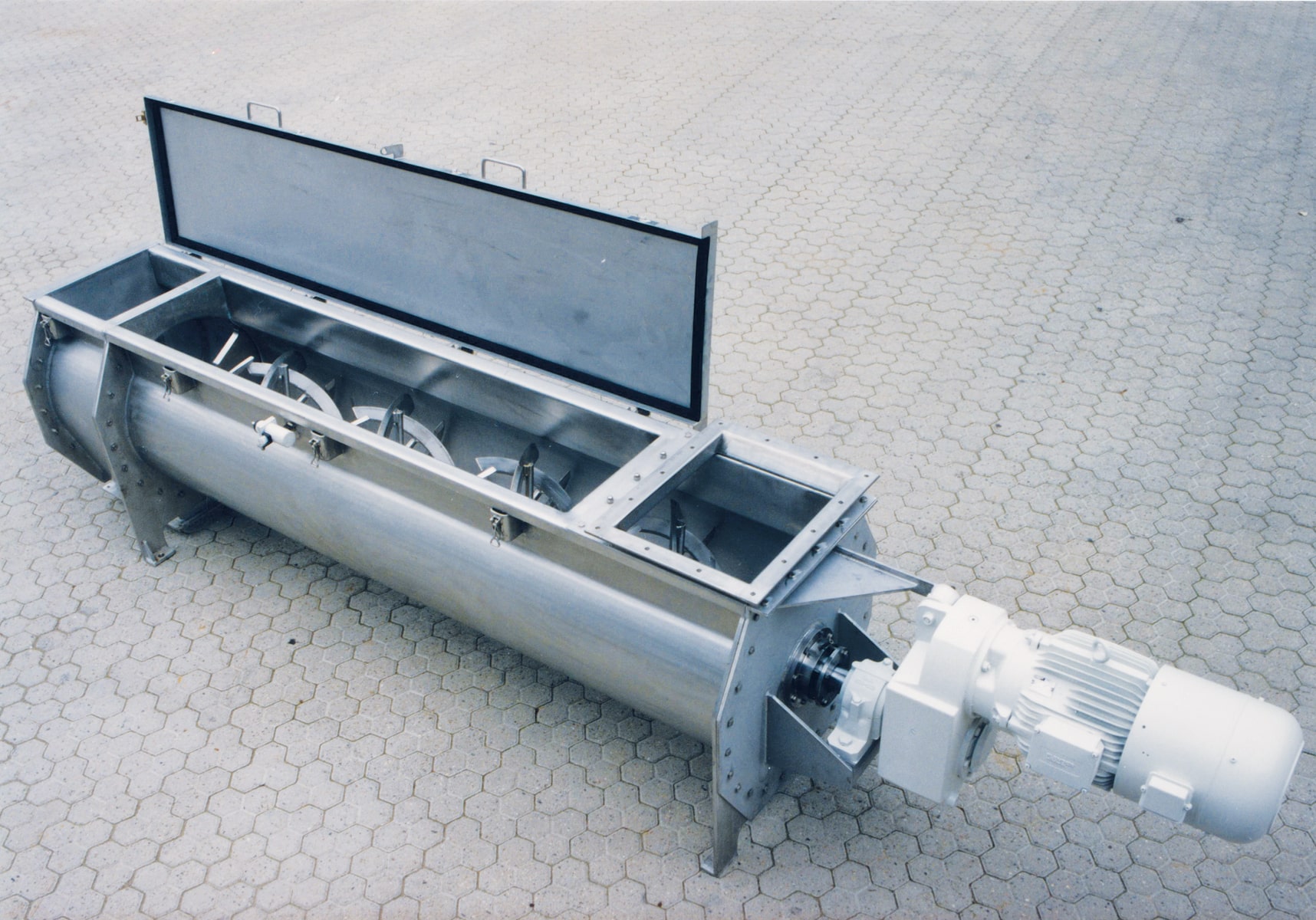

Construction of Ribbon Blender

Table of Contents

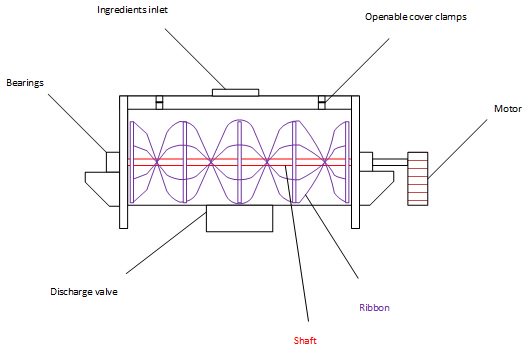

A ribbon blender consists of a U-shaped horizontal trough or shell containing a helical double-ribbon agitator that rotates inside. The shaft of the agitator is positioned in the center of the trough on which the helical ribbons (also called spirals) are welded. Since the ribbon stirrer consists of a set of internal and external helical ribbons, it is also called a “double” helical ribbon agitator. The counteracting blades are provided for high shear as well as for breaking lumps or aggregates. The ribbon blenders are powered by a drive system consisting of a motor, a gearbox, and couplings. They are generally powered by a 10 HP to 15 HP motor for 1000 kg of product mass to be blended. The specific power ranges from 3 to 12 kW/m² according to the products to be mixed. The area where the shaft exits the container is envisaged with a Sealing arrangement to ensure that the material does not move from the container to the outside. The material is charged into the mixer usually by feed hoppers. It is also equipped with a bottom discharge spout.

Working of Ribbon Blender

The materials to be blended are loaded into the blender, typically filling it between 40 and 70 percent of the total volume of the container. Ribbons are allowed to rotate with the help of the drive system. During the blending operation, one blade slowly moves the solids in one direction and the other moves them rapidly in the opposite direction. As a result, homogeneous blending is achieved in a short time. The mixing is generally carried out in 15 to 20 minutes. After blending, the material is discharged from a discharge spout located at the bottom of the trough.

Particle size and bulk density have the strongest influence on the mixing efficiency of the ribbon mixer. Ingredients having a similar particle size and bulk densities tend to mix faster than the ingredients with a variation of these attributes.

Advantages of Ribbon Blender

- Ribbon blenders can be operated in both batch and continuous modes.

- High shear by baffles cause break down of aggregates

- Less headspace requirement

Disadvantages of Ribbon Blender

- It is practically difficult to obtain 100% discharge in the ribbon blender.

- Higher clearance between the external periphery of the outer ribbon and the container may result in unmixed or dead spots.

- The movement of ribbons near the vessel walls due to high shear and compression can damage fragile materials and cause attrition.

Variant of Ribbon Blender

- An alternate design of the ribbon agitator is the paddle agitator which can handle a fragile material. The paddle agitator is composed of both forward and reverses paddles in place of the ribbon. The paddles are positioned to move the material in opposing lateral directions as well as in a radial direction. The paddle design is generally used when friable materials are mixed, and when batches as small as 15% of the total capacity are going to be blended into the blender

Pharmaceutical applications

- A ribbon blender is used for blending large volumes of dry solids, wet solid mass, bulk drugs, chemicals, and cosmetic powders.

Make sure you also check our other amazing Article on : Twin Shell Blender (or) V Cone Blender