Short Note on Jute: The jute fibre is collected from the stem bark of the white jute plant and to a lesser extent Tossa jute belongs to species Corchorus i.e. C. capsularis and C. olitorius.

Family: Tiliaceae or Malvaceae.

Distribution: Jute is cultivated in Bangladesh, Nepal, Myanmar, India, Thailand, China, Pakistan, Japan, UK, France, Egypt, and Spain. In India, the major production of jute is in West Bengal, Assam, and Bihar.

Description of Plant:

Table of Contents

The plants are annual herbs with 2-4 m in height. They are unbranched or with a few side branches. The leaves are alternate, simple, and lanceolate in shape (Fig.1). They are 5-15 cm long, with an acuminate tip and a finely serrated or lobed margin. The flowers are 2-3 cm in diameter and are yellow.

Production of Fibre:

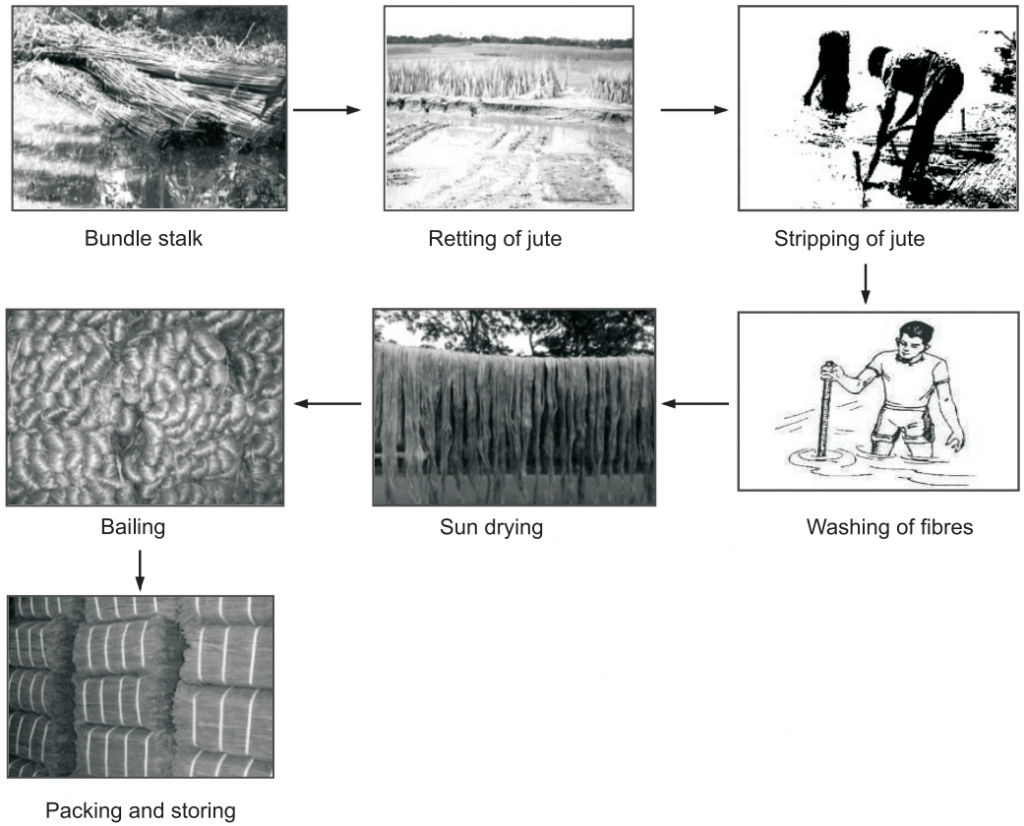

The unbranched stems of the jute plant are cut and formed into a bundle. This should carry out before the flowering stage. The jute fibre comes from the stem and ribbon (outer skin) of the jute plant. The fibres are first extracted by the retting method either in a pond or any waterlogged condition. Retting is a microbial process by which the jute plant is immersed in water and the fibre is loosened from the woody core of the jute plant. This process softens the tissues and breaks the hard pectin bond between the bast and jute hurd (inner woody fibre stick) and the process permits the fibres to be separated. It has been found that jute stems ret most rapidly at 34ºC. At this temperature, it takes generally 8-12 days for complete retting. The retting process consists of bundling jute stems together and immersing them in slow running water. After the retting process, stripping begins. In the stripping process, non-fibrous matter is scraped off, leaving the fibres to be pulled out from within the stem and washed in clear, running water. Then they are hung up or spread on thatched roofs to dry. After 2-3 days of drying, the fibres are tied into bundles. The jute fibres are graded according to the colour, length and smoothness of the fibres (Fig.2).

Physical Properties:

- Colour: Golden yellow

- Odour: Characteristic

- Taste: None

- Size: Average length is 1 to 4 m and diameter from 17 to 20 microns

- Appearance: Jute is long, soft and shiny

- Specific gravity: 1.5 g/mm3

- Moisture regain: 13.75% Strength

- Elongation: 1.7% at the break

Chemical Properties:

- Effect on acids: Easily damaged by hot dilute acid or cold concentrated acid

- Effect on alkali: Fibres are damaged by strong alkali, on heating with sodium hydroxide, fibres lose weight

- Effect of light: Due to the presence of lignin, fibres change the colour slightly.

- Effect of dyes: Basic dyes are used to colour the fibres

- Effect of bleaches: No effect with H2O2, KMnO4.

Chemical Constituents: Jute fibres contain mainly cellulose (60%) and hemicellulose (24%). Apart from that Lignin, fats and wax are also present.

Uses:

Jute is the second most important vegetable fibre after cotton. Jute is used chiefly to make cloth for wrapping bales of raw cotton and to make sacks and coarse cloth. The fibres are also woven into curtains, chairs, coverings and carpets. The fibres are used alone or blended with other types of fibres to make twine and rope.

Substitutes: Fibres of Hibiscus cannabinus are used as substitutes for jute fibres.

Make sure you also check our other amazing Article on : Classification of Fibres