Principle

Table of Contents

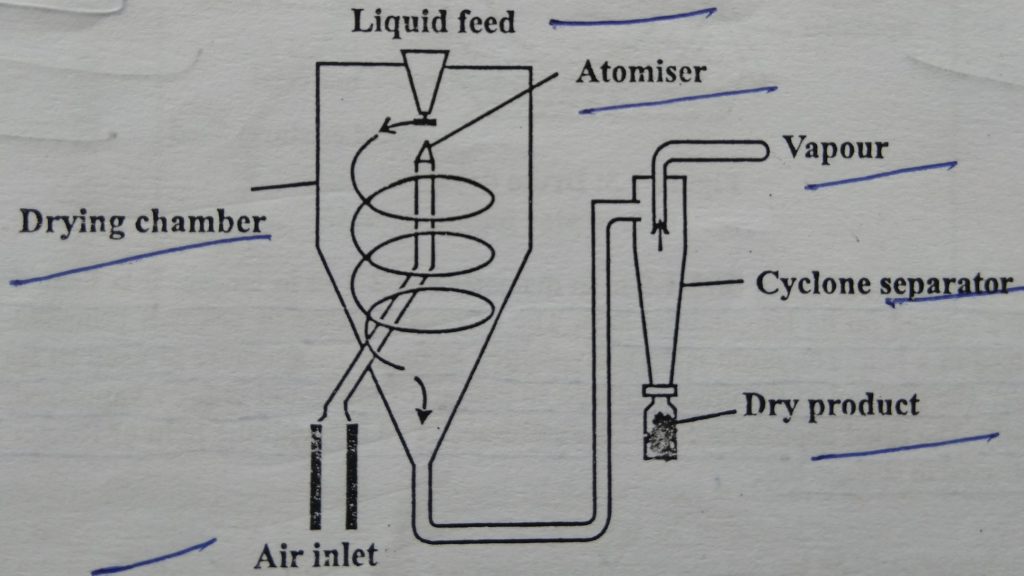

The spray dryer provides a large surface for heat and mass transfer by atomizing the liquid into small droplets. These are sprayed in a stream of hot air so that each drop dries to get a solid particle.

Construction of Spray Dryer

It consists of a drying chamber having a conical base. It is made of stainless steel. The inlet for hot air is also provided at the bottom and another inlet for spray disk atomizer at the top. Atomization may be achieved using single-fluid or two-fluid nozzles The drying chamber is connected to a cyclone separator. The dry product is collected from the bottom of the cyclone separator

Working of Spray Dryer

The spray-drying process can be divided into four sections

- atomization of the fluid,

- mixing of the droplets

- drying.

- removal and collection of the dry particles:

The feed entered the drying chamber through the atomizer. The jet atomizer and Rotary atomizer are used. Jet atomizers get easily blocked resulting in variation of the size of the droplets. Rotary atomizers are preferred to avoid this problem. Hot air passes through the inlet. The air temperature should be adjusted in such a way that the droplet dries completely before reaching the wall of the drying chamber. The residence time of a droplet in the dryer is only a few seconds (5-30 s). The particle should not be overheated. The bottom of the drying chamber is connected to the cyclone separator. In the cyclone separator, the centrifugal force throws out the dried particles to the bottom and dried particles are collected in a bin. The vapors are removed from the top.

Advantages

- The process of drying completes within 3 to 30 seconds.

- Fewer labor costs are required as it is a continuous process.

- Uniform and controlled size products can be obtained.

- The product obtained has high bulk density and shows excellent solubility.

- The solutions or suspensions can be dried easily

- It is suitable for the drying of sterile products.

Disadvantages

- The spray dryer is expensive.

- Difficult to operate.

- The thermal efficiency is low, as much heat is lost in the discharged gases.

Pharmaceutical Applications

- A spray dryer can be used for drying both solutions or suspensions.

- Spray dryers are very useful for the drying of heat-sensitive substances.

- Citric acid, borax, sodium phosphate, hexamine, gelatine, and extracts are dried by this method.

- The suspensions of starch, barium sulfate, and calcium phosphate are also dried by the spray dryer.

- Milk, soap, and detergents are also dried by a spray dryer.

- A spray dryer is used compulsorily if the quantity of the materials to be dried is large and the products are hygroscopic or undergo chemical decomposition.

- Some of the products that are dried using the spray dryer are acacia, adrenaline, bacitracin, blood, boric acid, calcium sulfate, coffee extract, dextran, fruit juices, ferrous sulfate, pepsin, pancreatin, plasma, serum, soaps, sodium phosphate, starch, sulfur, vaccines vitamins, yeast, etc.

Make sure you also check our other amazing Article on : Drum Dryer or Roller Dryer