Stability testing of emulsions involves determining stability at long-term storage conditions, accelerated storage conditions, freezing and thawing conditions. Stress conditions are applied to speed up the stability testing.

- The stress conditions used for speeding up instability of emulsions include. Centrifugal force, Agitational force, Aging, and temperature.

- Physical parameters are evaluated to assess the effect of any of the above stress conditions:

(a) Phase separation

(b) Viscosity

(c) Electrophoretic properties

(d) Particle size and particle count

1. Determination of particle size and particle count: Determination of changes in the average particle size or the size distribution of droplets is an important parameter used for the evaluation of emulsions. It is performed by optical microscopy, sedimentation by using Andreasen apparatus and Coulter counter apparatus.

2. Determination of viscosity: Determination of viscosity is done to assess the changes that might take place during aging. Emulsions exhibit a non-newtonian type of flow characteristics.

The viscometers which should be used include cone and plate viscometers.

3. Determination of phase separation: This is another parameter used for assessing the stability of the formulation.

Phase separation may be observed visually or by measuring the volume of the separated phases.

4. Determination of electrophoretic properties: Determination of electrophoretic properties like zeta potential is useful for assessing flocculation since electrical charges on particles influence the rate of flocculation.

Types of Surfactants:

- Anionic

- Cationic

- Non-ionic

- Ampholytic

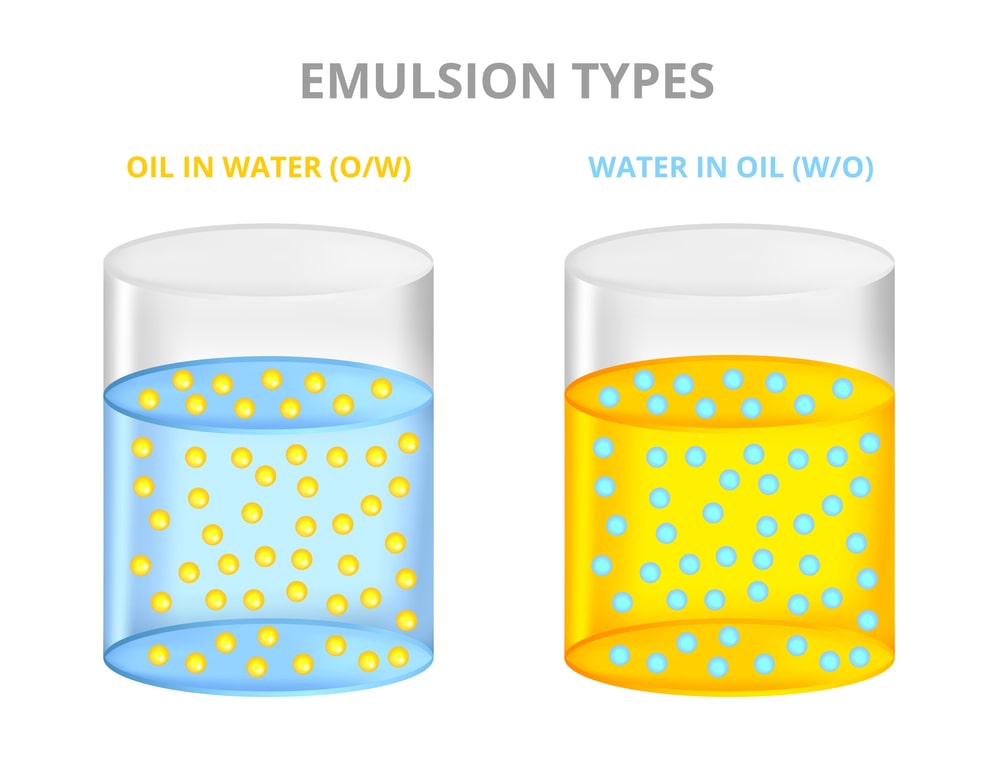

(a) Anionic: Monovalent, polyvalent, and inorganic soaps sulfates and sulphonates, alkali soaps include sodium, potassium, and ammonium salts are lauric, myristicin, palmitic, stearic, and oleic acid are water-soluble which forms o/w emulsion.

Metallic soaps like calcium or magnesium salts are fatty acid are water-insoluble and tend to form w/o emulsion. Organic soaps form o/w emulsion. Sulfated alcohols such as sodium lauryl sulfate form o/w emulsion.

Sodium dioctyl sulphosuccinate is frequently used sulphonates di-(2-ethyl hexyl) sodium sulphosuccinate called Aerosol OT.

(b) Cationic emulgent: They are commonly used in lotion and cream due to their remarkable bactericidal property. For example, domiphen bromide, cetyl pyridinium bromide, benzalkonium chloride, cetyl trimethyl ammonium bromide.

(c) Non-ionic emulgents: For example, Glyceryl ester, fatty acid esters of sorbitol, and their polyoxyethylene derivative, polyoxyethylene glycol esters, and Sorbitan fatty acid esters e.g. Sorbitan mono palmitate (span-40) are non-ionic and oil-soluble promoting w/o emulsion.

Polyoxyethylene sorbitan mono-palmitate (tween 40) is a hydrophilic, water-soluble derivative that promotes o/w emulsion.

(d) Amphoteric: N-dodecyl, N, N-dimethyl betaine, lecithin.

PEG esters such as polyoxyethylene glycol 400 monostearate are widely used to prepare emulsified lotions and creams.

Natural emulgents: Most commonly used is acacia. Others are Gelatin which is amphoteric, Lecithin (phospholipid), and Cholesterol.

Acacia and gelatin: Form interfacial monolayer.

Lecithin and cholesterol: Form interfacial monomolecular layer.

Lecithin is a phospholipid and forms o/w emulsion, Darken on storage.

Cholesterol form: w/o emulsion.

Finely dispersed solids: Colloidal clays such as bentonite, veegum, oxide, silica gel, aluminum hydroxide, Magnesium oxide. Magnesium hydroxides are the most commonly used finely dispersed solids that act by forming a particular particulate film around dispersed globules.

- Bentonite produces both o/w and w/o types of emulsion depending on the order of mixing.

- Veegum is also an emulgent for o/w emulsion but it is chiefly used as a stabilizer in cosmetic creams and lotion.

- Auxiliary emulgents are incapable of forming a stable emulsion. Have thickening property. Thus, consistency of an o/w emulsion prepared by using acacia. It can be increased by tragacanth or agar which act as an auxiliary emulsion.

List of antioxidants (0.001-0.1%)

- Gallic acid

- Propyl Gallate

- Ascorbic acid

- Sulfites

- Alpha-Tocopherol

- Butylated hydroxyl toluene

- Butylated hydroxyanisole

- Ascorbyl palmitate

Make sure you also check our other amazing Article on : Preparation of Emulsions