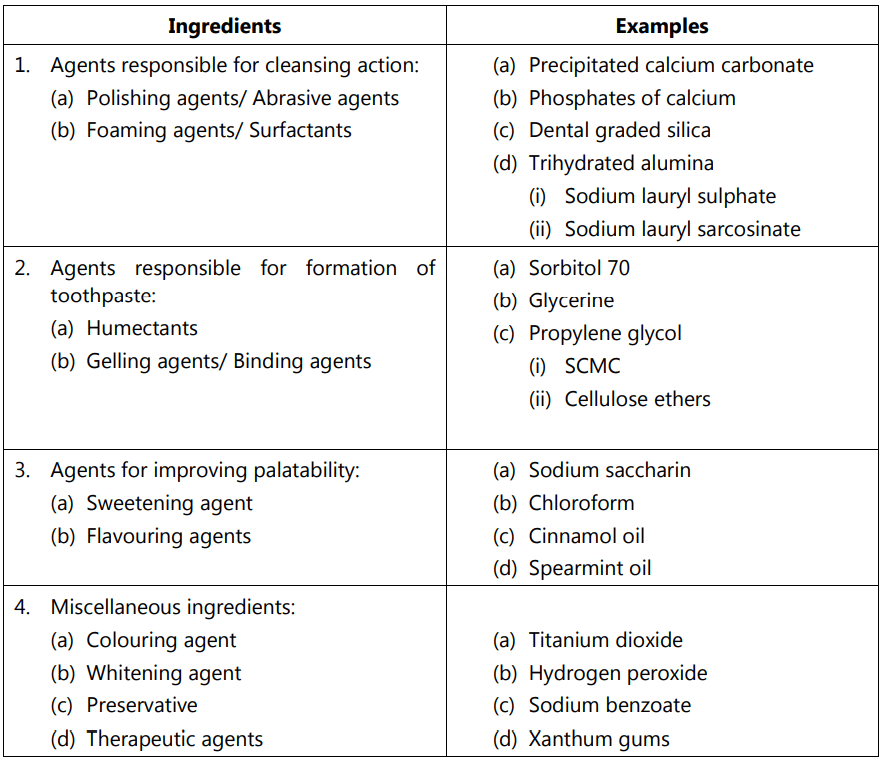

Formulation and Evaluation of Toothpaste: Dentifrices such as toothpaste, toothpowder, and tooth gel are meant for cleaning the surface of the teeth by removing the food debris and plaque adhered to the surface of the teeth which is the main cause for a tooth problem.

Formulation of Tooth Pastes

Table of Contents

1. Polishing Agents/ Abrasive Agents:

(a) Precipitated calcium carbonate: Also known as precipitated chalk and is available in several grades.

Advantages:

- It is of very low cost.

- Available in different grades in white or off-white color.

Disadvantage:

- It is incompatible with sodium fluoride which is used as an anticaries agent.

(b) Phosphates of calcium: A large variety of insoluble calcium phosphate are used as abrasive agents.

Advantages:

- It provides good flavor stability.

- It has a less abrasive effect on dentine.

Disadvantage:

- It is incompatible with sodium fluoride.

(c) Dental grade silica: These are polymers of silica that are used as an abrasive agent in the formulation of toothpaste in large quantities. These are available in two forms:

(i) Abrasive form of silica.

(ii) Thickening form of silica.

Advantages:

- Mostly used as abrasive in gels.

- They are inert and easily compatible with other ingredients.

Disadvantage:

- Abrasive property is not consistent.

(d) Trihydrated alumina: It is available as suspension or crystalline powder.

Advantages:

- It is less costly.

- It possesses stability with fluorides.

Disadvantage:

- It has poor thickening properties.

2. Foaming Agents/ Surfactants:

These are also known as wetting agents. The mechanism of cleansing action is by reducing the surface tension at the interface of the adhered material and enamel of the teeth.

The properties of the surfactant are as follows:

- Should be compatible with other ingredients of the formulation.

- Should possess good surface-active property.

The most commonly used surfactants are:

(a) Sodium lauryl sulfate.

(b) Sodium lauryl sarcosinate.

3. Humectants:

Humectants are used to prevent the rapid drying of dentifrices. They prevent excessive moisture loss from the product. They may additionally impart plasticity to the final product.

The most commonly used humectants in the formulation of dentifrices are as follows:

(a) Sorbitol 70

(b) Glycerin

(c) Propylene glycol

Preparation of Toothpaste

Toothpaste is prepared by following methods:

1. Dry gum method

2. Wet gum method

1. Dry Gum Method:

(a) All solid components except surfactants are mixed in a dry mixer.

(b) The liquid components such as humectants and water are gradually added to the dry mix.

(c) The mixing is carried out till a smooth paste is formed.

(d) The remaining ingredient such as surfactant and flavoring agents are added to paste under vacuum.

2. Wet Gum Method:

(a) All liquid components are mixed to form a liquid phase.

(b) The binding agent is mixed with liquid phase with uniform stirring.

(c) The solid ingredients excluding the surfactants are gradually added to the mucilage with uniform mixing in an agitation mixer, to form a homogeneous paste.

(d) The remaining ingredients i.e. surfactants, flavoring agents, coloring agents are added under vacuum to the homogeneous paste.

Evaluation of Toothpaste

1. Tests for Abrasive Character: The cleansing action of dentifrices mainly depends on their abrasive property. The abrasion should not lead to any damage to the enamel and hence the test for checking abrasion has been done on the extracted teeth.

2. Determination of particle size: The particle size is determined by microscopical techniques or by involving the method of sieving.

3. Test for cleansing property: In this the tooth cleanser such as powder, paste are brushed onto polyester film and the change in reflectance character of lacquer coating is measured.

4. Determination of the consistency of the product: For the maintenance of the flow property throughout the storage period, determination of the consistency is done.

5. Determination of pH of the product: 10% solution of the paste in water is made and pH of the dispersion is measured using a pH meter the pH should be in the range of 4.4 to 6.8 to maintain the consistency of the product.

Make sure you also check our other amazing Article on : Preparation of Shampoo