Principle

Table of Contents

In the ball mill, Impact and Attrition both are responsible for the size reduction Rapidly moving balls are used for the comminution of brittle material.

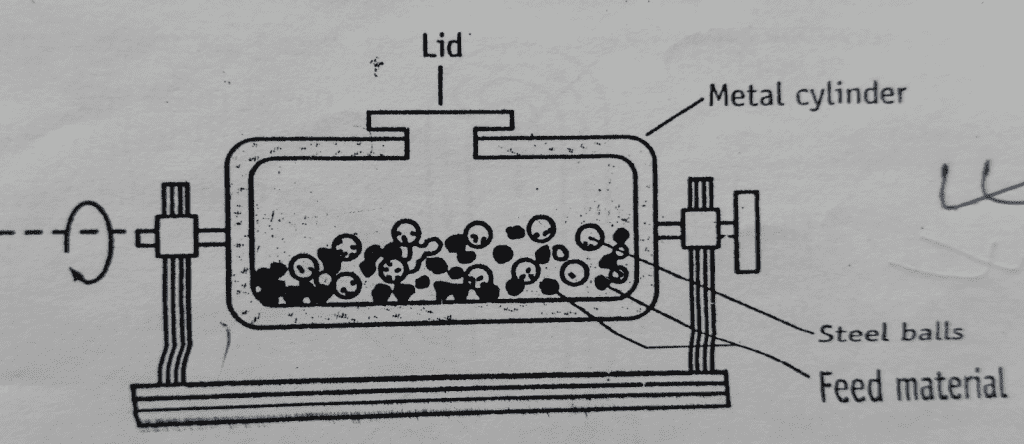

Construction of Ball Mill

The ball mill consists of a hollow metal cylinder mounted on a shaft and rotating about its horizontal axis. The cylinder can be made of metal, porcelain, or rubber. Inside the cylinder balls or pebbles are placed. The balls occupy between 30 and 50% of the volume of the cylinder. The diameter of the balls depends on the size of the feed and the diameter of the cylinder. The diameter of the balls varies from 2cm to 15cm. The balls can be made of metal, porcelain, or stainless steel. The ball acts. as a grinding medium.

Working of Ball Mill

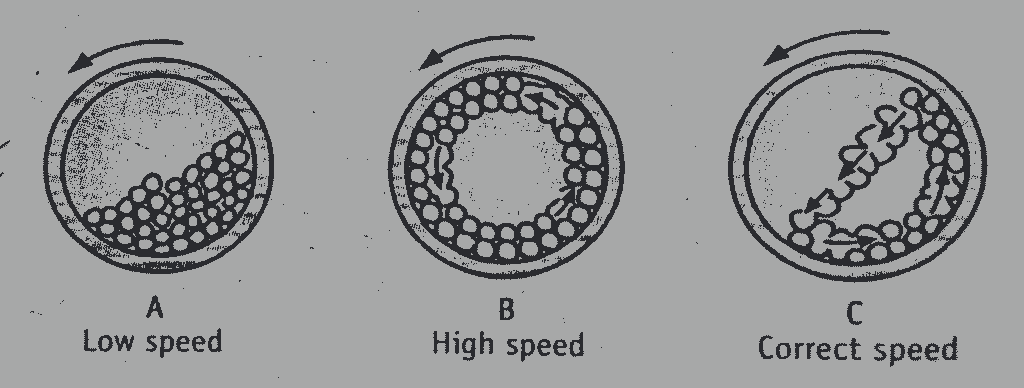

The material to be ground is kept in a hollow cylinder. The material is placed up to 60% of the volume. A fixed number of balls is placed in the cylinder and then the cylinder is closed. The mill is allowed to rotate. Speed of rotation is an important point of consideration.

At low speed, the mass of balls will slide or roll up one over another and will only produce an insignificant amount of size reduction. At high speeds, the balls are thrown to the cylinder wall due to centrifugal force and no grinding will occur. At 2/3rd speed centrifugation just occurs which is called the critical speed of the ball mill. At this speed, the balls are carried almost to the top of the mill and then fall in a cascade across the diameter of the mill. In this way, the maximum size reduction is obtained by the impact of the particles between the balls and by attrition between the balls. It is usually 0.5 cycles per second (cps).

Advantages of Ball Mill

- Very fine powder can be obtained.

- Suitable for both wet and dry grinding processes.

- Toxic substances can be ground, as closed cylinders are used.

- Sterility can be maintained due to a closed cylinder system.

- In a ball mill, installation, operation, and labor costs are low.

- Suitable for batch or continuous process.

- Grinding medium is cheap

- The cost of installation and production is low.

Disadvantages

- The ball mill is a very noisy machine especially when a metal cylinder is used.

- Ball mill is a slow process.

- The soft, tacky, fibrous material cannot be milled by a ball mill. These materials may cause problems by caking on the sides of the mill

- Wear occurs from the balls and the inside surface of the cylinder hence there is a possibility of contamination of the product with mill material.

Applications

- A size of 5 to 100 mm or less is obtained.

- Ophthalmic and parenteral products can be produced.

Various types of Ball Mills

- Hardinge mill: In this type of ball mill the cylinder has a conical end towards a discharge point, In this mill, the larger balls remain inside the cylinder and the smaller balls are placed in the conical portion. As a result, coarser grinding occurs in the cylinder portion and a finer grinding takes place at the apex of the conical part. The product is finer and more uniform than the general cylindrical ball mill.

- Tube mill: Tube mills are generally charged with flint pebbles instead of metal balls. Tube mill can grind finer products than the conventional ball mill. Their construction is also simple and generally used for grinding hard material. Tube mill has a higher length/ diameter ratio as compared to Ball mill.

- Rod mill: This is a modification of the tube mill. Instead of balls or pebbles, rods are used as grinding material. TTheserods are useful with sticky materials since rods do not form aggregates like balls.

- Vibration mill: In this type of mill vibratory movements are given instead of rotation. The cylinder is mounted on springs which set up vibration by electromagnetic means. The cylinder moves through a circular path with an amplitude of vibration up to about 20mm and a rotational frequency of 15 to 50 per second. Grinding efficiency is also better in this type of mill.

- Continuous ball mill: This equipment is placed on a small slope so that the powder can pass from one chamber to the next chamber through a screen attached to each chamber so that finally fine product can be obtained.

Make sure you also check our other amazing Article on : Working of Hammer mill