Principle:

Table of Contents

Size reduction is done by crushing (compression) due to the heavyweight of the steel pestle. Shearing stress is also involved during the movement of mortar and pestle.

Construction of End Runner Mill:

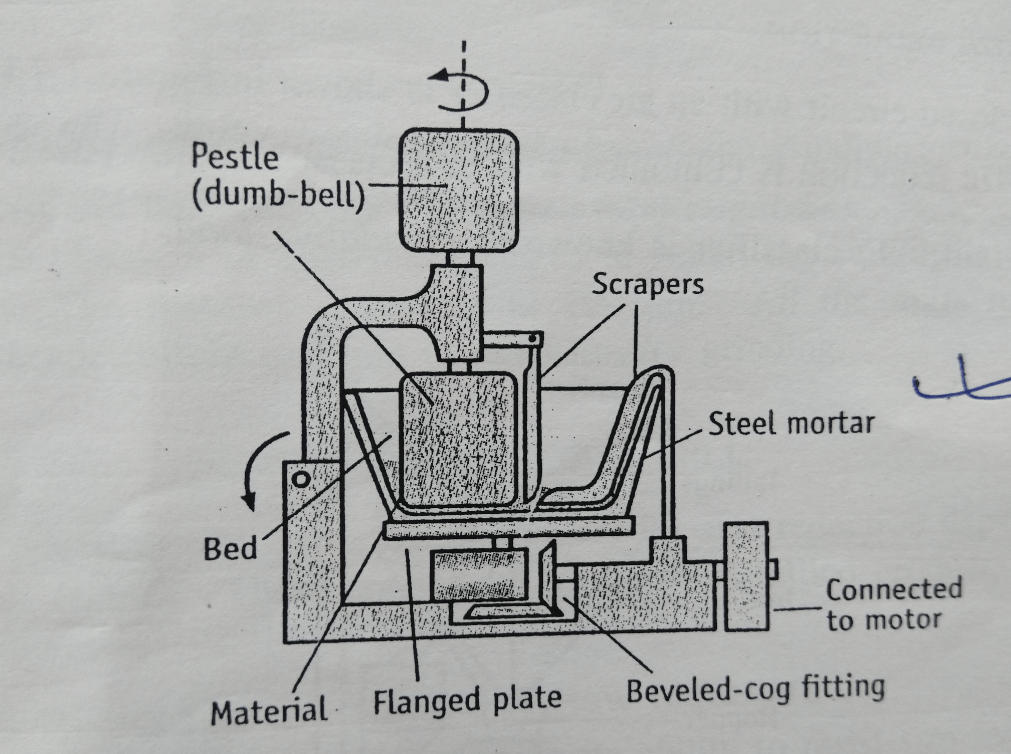

- The construction of an end runner mill is shown in Figure. It is considered a mechanical mortar and pestle. It consists of a steel mortar, which is fixed to a flanged plate. Underneath the flanged plate, a beveled cog fitting is attached to a horizontal shaft bearing a pulley. Hence, the plate with mortar can be rotated at a high speed.

- The pestle is dumb-bell shaped so that balancing and efficient grinding by its weight can be achieved. The bottom of the pestle is flat rather than round. The pestle carries an arm, which is hinged. By this arrangement, the pestle can be raised from the mortar to facilitate emptying and cleaning. The narrow central portion of the pestle is longer than the band of the arm around it. Hence, pestle can rise and fall over the material in the mortar.

Working of End Runner Mill:

- The material to be ground is placed in the mortar. The scraper puts the material in the path of the pestle. The mortar revolves at a high speed. The pestle is placed in the mortar. The rotating mortar causes the pestle to revolve. During this process, size reduction is achieved by shearing as well as crushing. The material is collected and passed through a sieve to get the powder of the desired size.

Uses:

- End runner mill is suitable for fine grinding.

Disadvantage:

- It is not suitable for drugs, which are in unbroken or slightly broken conditions

Make sure you also check our other amazing Article on : Edge Runner Mill