Principle:

Table of Contents

The size reduction is done by crushing (compression) due to the heavy weight of stones. Shearing force is also involved during the movement of the stones.

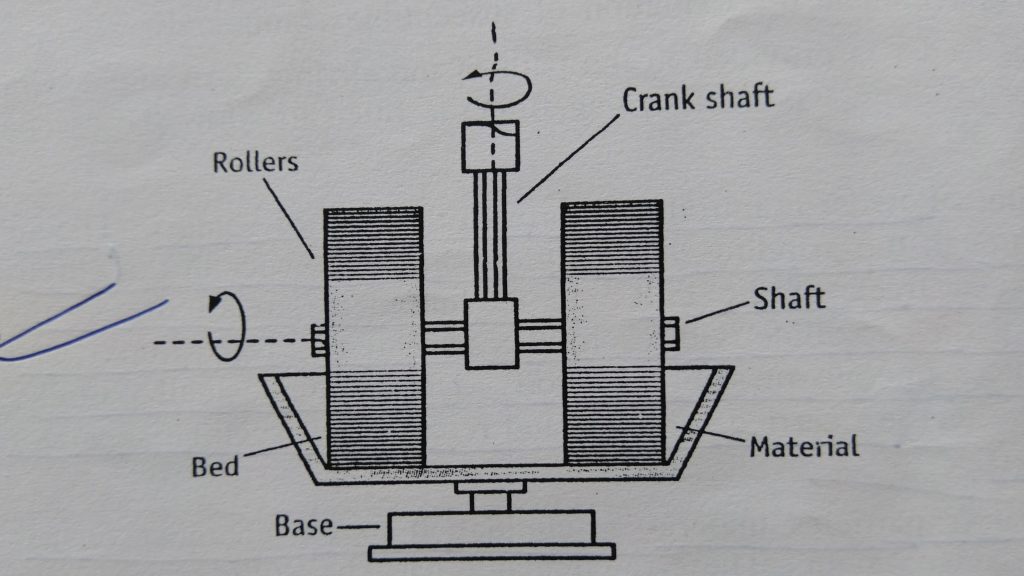

Construction of Edge Runner Mill:

- The construction of an edge runner mill is shown in Figure. It consists of two heavy rollers and may weigh several tons. The rollers move on a bed, which is made of stone or granite. Each roller has a central shaft and revolves on its axis. Further, the rollers are mounted on a horizontal shaft and move around the bed.

Working of Edge Runner Mill:

- The material to be ground is placed on the bed. With the help of a scrapper, it is kept in the path of the stone wheel. The stones revolve on their axes, and at the same time travel around the shallow stone bed. The outer part of the wheel has to travel a greater distance so that size reduction is achieved by shearing as well as the inner, as crushing. The material is ground for a definite period. The powder is collected and passed through a sieve to get powder of the required size. It is a batch process.

Uses:

- It is used for grinding tough materials to a fine powder. It is still used for plant-based products, while more sophisticated mills are used for chemicals and drugs.

Advantages:

- It does not require attention during operation.

Disadvantages:

- It occupies more space than other commonly used mills.

- Contamination of the product with roller material is possible.

- The milling process is time-consuming.

- It is not used for sticky materials.

- Energy consumption is quite high.

Make sure you also check our other amazing Article on : Fluid Energy Mill