Formulation of Lipstick: Lipsticks can be defined as a dispersion of the colouring matter in which a base consisting of a suitable blend of oils, fats and waxes with suitable perfumes and flavours moulded in the form of sticks to impart attractive gloss and colour when applied on lips. Lipsticks impart a moist appearance to the lips by disguising their defects.

Ideal Characteristics of Good Lipsticks

Table of Contents

The ideal requirements for a good lipstick may be as follows:

- It should effectively cover lips with colour and impart a gloss that would last long.

- It should not alter the degree of its shade and maintain the intensity of colour.

- It should adhere firmly to the lips and should not provide any grease, appearance.

- It should possess good shear thinning properties to deposit the colour with minimum pressure.

- It should show a smear-proof colouring effect.

- It should possess the required plasticity and be able to maintain all the properties throughout the storage period.

- It should not be grainy.

- It should be easily dried.

- The stick should possess even firmness and should maintain its strength at varying temperatures up to 55°C.

- The stick should not dry or break easily.

- The lipstick should possess a nice aroma and a good flavour.

- It should be safe and non-irritating to the lips.

- It should not result in blooming or sweating of the lips.

Formulation of Lipstick

Composition:

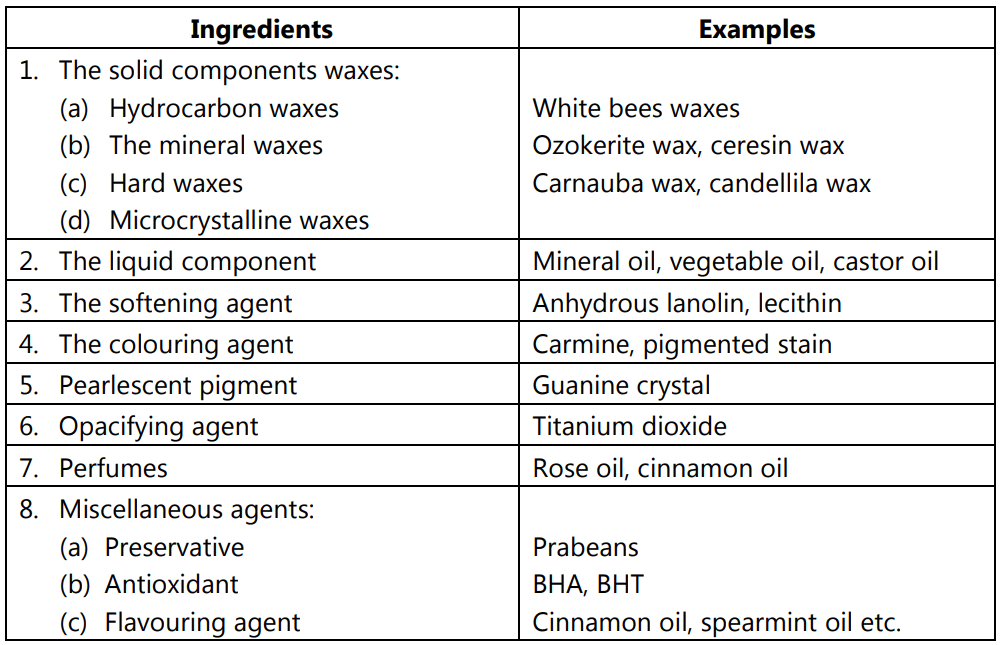

1. The Solid Components/Waxes:

The solid components are responsible for the final structure of the product by solidifying the liquid matrix.

(a) Hydrocarbon waxes: White beeswax: It is also known as common wax and forms the oily base in the formulation of the lipstick.

Uses:

- It forms the important base to entrap the castor oil.

- It has good elastic properties and can be readily deformed.

- It is used as a traditional stiffing agent.

Advantages:

- It is compatible with vegetable minerals and animal waxes.

- It can be moulded to the required form.

Disadvantage: If the concentration is more than 20% then it forms a dull film.

(b) Mineral waxes: Microcrystalline waxes have replaced the mineral waxes but are still used as the same name.

(i) Ozokerite wax:

Uses:

- It increases the melting point of the base.

- It can be easily transferred to the required base.

Advantage: It is available on different bases.

Disadvantage: It may be subjected to adulteration.

(c) The hard waxes: These are mainly responsible for the shape and hardness of the lipstick.

Uses:

- Provide rigidity to the stick

- Helps in modifying by shrinking the stick

Disadvantage: It is not miscible with the other waxes and remains as a separate solid phase

(d) Microcrystalline waxes: These are hydrocarbon containing long carbon chains.

Uses: Maintains crystal structure of the lipstick.

Disadvantage: Possess low solubility in castor oil.

2. The Liquid Components:

These are mostly constituted by oil such as mineral oil, vegetable oil, castor oil, alcohol, etc.

(a) Minerals oils :

- Contain a blend of hydrocarbon from the petroleum source.

- Available as light mineral or heavy mineral oil.

(b) Vegetable oil: sesame oil and olive oil may be used.

(c) Castor oil: Obtained from the castor plant, Ricinus Communis.

- Forms valuable lipstick base.

- High viscosity and good dissolving power.

- Posses stability towards oxidation.

- Easily compatible with other ingredients.

Preparation of Lipstick

Successful preparation of lipstick shades depends upon the adequate dispersion of the lake colours in the lipstick mass. It is advisable to prepare the dispersion of lake colours in castor oil. Dispersions arc generally prepared by milling about 25% concentration of lakes in castor oil.

Method of Preparation:

- If the solvent is used for the dissolution of Bromo acid, the solution is first prepared and set aside.

- If commercial colour pastes are not used, then lake colours are first dispersed by mixing.

- The colour paste is passed through the triple roller mill until it becomes soft and free from brittle particles.

- The colour acid is now mixed with the Bromo acid mixture.

- All ingredients are then arranged in increasing order of their melting point.

- This mixture is milled until it is perfectly smooth.

- Preservative and anti-oxidant are mixed in the remaining oil.

- Finally perfume is added and mass is stirred.

- Automatic ejection mould is preferred for large scale production.

- The mould is lubricated with liquid paraffin or isopropyl myristate before pouring mass into the mould.

- It is important to prevent settling down of colouring mass when moulds are cooled.

- Lubrication facilitates the easy removal of the stick.

Evaluation of Lipsticks:

The efficiency, stability and consistency of the finished product can be determined by the evaluation studies

The evaluation tests for the lipsticks are as follows:

1. Melting point determination test: The determination of melting point is done to determine the storage characteristics of the product.

The melting point of the lipstick base should be between 60-65o C which will avoid the sensation of friction or dryness during application.

The method of determination is known as the capillary tube method :

(a) Here in this method, about 50 mg of lipstick is taken and is inserted into a glass capillary tube open at both ends.

(b) The capillary tube is ice cooled for about 2 hours and then placed in a beaker containing hot water and a magnetic stirrer.

(c) The temperature at which material starts moving through the capillary is said to be the melting point temperature.

(d) Another important parameter is the droop point which determines the temperature at which the product starts oozing out the oil and becomes flattened out.

2. Microbiological test: The test is carried out to determine the extent of contamination either from the raw materials or mould. The test involves the plating of a known mass of sample on two different culture media for the growth of microorganisms and incubating them for a specific period. The extent of contamination can be estimated by counting the number of colonies.

3. Test for rancidity: The oxidation of oil such as castor oil and many other ingredients may result in bad odour and taste and also result in a sticky product. The test for rancidity can be done by using hydrogen peroxide and determining its peroxide number.

4. Test for the application force: This is a test to determine the force to be applied during application. In this method, two lipsticks are cut to obtain flat surfaces which are placed one above the other. A smooth paper is placed between them which is attached to a dynamometer to determine the force required to pull the paper. The pressure reading indicates the force of application.

5. Storage stability: This test is done to determine the stability of the product during storage.

6. Stability to oxidation: The oxidative characteristics of the finished product are determined to check the stability of the product to oxidation. The extent of oxidation can be determined by the peroxide number of the product after exposure to the substance to oxygen for a specific period.

7. Determination of surface characteristics: The study of the surface property of the product is carried out to check the formation of crystals on the surface or the contamination by microorganisms or formation of wrinkles or the exudation of liquids.

8. Determination of colour dispersion: The test is done to determine the unit or the dispersion of the colour particles.

Make sure you also check our other amazing Article on : Contact Lens Solution