Principle: The limit test for arsenic is based on reducing the arsenic in the arsenious state to the arsine gas (AsH3) with zinc and hydrochloric acid. The arsine gas stains the mercuric chloride paper yellow. The sample is dissolved in acid whereby the arsenic present as impurity in the sample gets converted to arsenic acid. The arsenic acid is reduced to arsenious acid by reducing agents like stannous acid, potassium iodine, etc. The nascent hydrogen formed during the reaction further reduces arsenious acid to the arsine gas. The arsine gas reacts with mercuric chloride paper to produce a yellow stain.

The depth of the yellow stain depending upon the amount of arsenic present in the sample, is compared with that of a standard stain produced from a known amount of arsenic.

Reactions:

As3+ → H3AsO4

H3AsO4 → H3AsO3

2AsH3 + HgCl2 → Hg(AsH2) + 2HCl

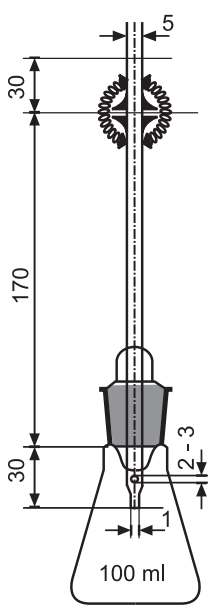

Apparatus for Limit Test for Arsenic (Dimensions in mm)

The apparatus consists of a 100.0 mL bottle or conical flask closed with a rubber or ground-glass stopper through which passes a glass tube (about 20 cm × 5 mm). The lower part of the tube is drawn to an internal diameter of 1.0 mm, and 15 mm from its tip is a lateral orifice 2 to 3 mm in diameter. When the tube is in position in the stopper the lateral orifice should be at least 3 mm below the lower surface of the stopper. The upper end of the tube has a perfectly flat surface at right angles to the axis of the tube. A second glass of the same internal diameter and 30 mm long, with a similar flat surface, is placed in contact with the first and is held in position by two spiral springs or clips. Into the lower tube insert 50 to 60 mg of lead acetate cotton, loosely packed, or a small plug of cotton and a rolled piece of lead acetate paper weighing 50 to 60 mg. Between the flat surfaces of the tubes place a disc or a small square of mercuric chloride paper large enough to cover the orifice of the tube (15 mm × 15 mm).

Fig.1: The apparatus (I.P. 1996)

Preparation: The solution of water-soluble substances is prepared with water and standard hydrochloric acid AsT. The solution of substances such as metallic carbonates, which effervesce with acids, is obtained with brominated hydrochloric acid AsT. The insoluble substances, e.g., BaSO4, bentonite, or kaolins, are diffused in water.

Preparation of Reagents/Solutions:

Hydrochloric acid AsT: Hydrochloric acid, low in arsenic, is commercially available.

Bromine solution: Dissolve 9.6 mL of bromine and 30 g of potassium bromide in a sufficient amount of water to make 100.0 mL.

Brominated hydrochloric acid AsT: It is prepared by adding 1.0 mL of bromine solution to 100.0 mL of hydrochloric acid.

Stannous chloride solution: It can be prepared by either of the following two methods.

- Dissolve 330 g of stannous chloride in 100.0 mL of hydrochloric acid and add sufficient water to make 1000 mL.

- Dissolve 60.0 mL of hydrochloric acid with 20.0 mL of water, add 20 g of tin, and heat gently until the evolution of gas ceases. Add sufficient water to make 100.0 mL. Store over a little of the undissolved tin remaining in the solution and protected it from air.

Stannous chloride solution AsT: It is prepared by adding stannous chloride solution to an equal volume of hydrochloric acid AsT, reducing it to the original volume by boiling and filtering through fine-grain filter paper.

Stannated hydrochloric acid AsT: It is prepared by adding 1.0 mL of stannous chloride solution AsT to 100.0 mL of hydrochloric acid AsT.

Standard Arsenic Solution (10 ppm As): Dissolve 0.330 g of arsenic trioxide in 5.0 mL of 2M sodium hydroxide and dilute to 250.0 mL with water. Dilute 1 volume of this solution to 100 volumes with water.

Zinc AsT: It is the granulated zinc that complies with the following additional test. To 10 g of the granulated zinc add 15.0 mL of the stannous chloride solution AsT and 5.0 mL of 0.1 M potassium iodide. Apply the general test but allow the reaction to continue for one hour. No visible stain should be produced on the mercuric chloride paper. Repeat the test by adding 0.1 mL of standard arsenic solution (10 ppm As); a faint but distinct yellow stain is produced.

Method:

The solution of the substances to be examined is prepared as specified in the individual monograph and transferred to the wide-mouthed bottle. To this, add 1 g of potassium iodide (5.0 mL of 1 M KI), 5.0 mL of standard hydrochloric acid solution, and 10 g of zinc AsT. Immediately place the glass tube in position and immerse the bottle in a water bath at a temperature such that a uniform evolution of gas is maintained. The most suitable temperature for the test is about 40°C. The reaction is allowed to continue for 40 minutes. After 40 minutes, the yellow stain produced on the HgCl2 paper is compared with the standard stain produced by treating 1.0 mL of the arsenic standard solution (10 ppm As) diluted to 50.0 mL with water in the same manner.

If the intensity of the yellow stain produced in the test solution is less than that of the standard stain, the sample passes the limit test for arsenic and vice-versa. The stain produced on paper fades on keeping and therefore the stains should be compared immediately.

Example: Perform limit test for arsenic in ammonium chloride IP.

| Sr. No. | Test | Standard |

| 1 | Place 50 mL of distilled water in a wide-mouth bottle of apparatus. | Place 50 mL of distilled water in a wide-mouth bottle of apparatus. |

| 2 | Add 2.5 g of ammonium chloride sample in the bottle and stir. | Add 1 mL of standard arsenic solution (10 ppm As) and stir. |

| 3 | Add 5 mL of standard hydrochloric acid. | Add 5 mL of standard hydrochloric acid. |

| 4 | Add 1 g of potassium iodide. | Add 1 g of potassium iodide. |

| 5 | Add 10 g of granular zinc. | Add 10 g of granular zinc. |

Interpretation: Place the glass tube fitting immediately to allow the reaction to proceed for 40 minutes in the dark and compare the yellow stain produced on the HgCl2 paper in two apparatus in daylight. For passing the test, the intensity of the yellow stain produced in the test sample should not be more than that of the standard.

Make sure you also check our other amazing Article on : Limit Test for Lead IP