Principle

Table of Contents

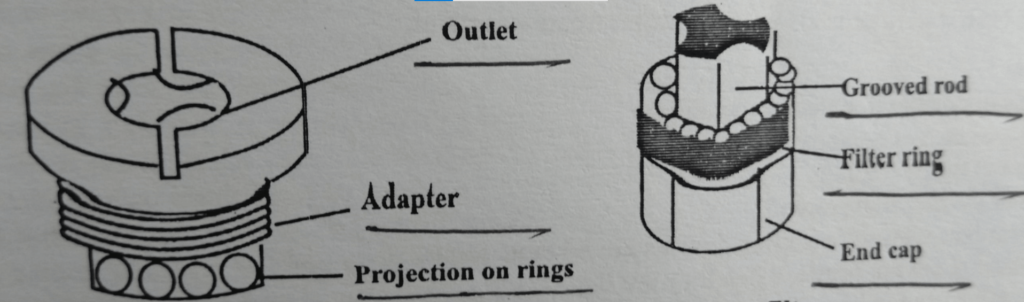

Meta Filters are a type of pressure filter. Pressure filters feed the product to the filter at a higher pressure than would be derived from gravity alone. This is the most common type of filter used in the processing of pharmaceutical products. The MetaFilter works as a strainer or filter for the separation of particles. The metal rings with several semicircular projections are arranged as a nest. Therefore channels are formed at the edges. This channel offers resistance to the flow of solids (forced particles). The clear liquid is collected into a receiver from the top.

Construction of Meta Filters

Meta filters consist of metal rings. These rings are made of stainless steel. They are approximately 15 mm in internal diameter, 22 mm in outer diameter, and 0.8 mm in thickness. These rings have several semicircular projections on one surface. The MetaFilter consists of a grooved drainage rod on which a series of metal rings are packed. The height of the projections and the shape of the ring section is such that when the rings are packed together in the same way upwards, and tightened on the drainage rod with a nut, narrowing channels are formed from approximately 250 µm down to 25 µm.

Working of Meta Filters

These metal filters are mounted in a container and can be operated by pumping slurry under pressure or, occasionally, by applying reduced pressure on the outlet side. The slurry passes through the channels formed at the edges between the rings. The clear liquid is raised and collected from the outlet to the receiver. In this way, the MetaFilter can be used as a strainer for coarse particles, but a bed of suitable material like kieselguhr is first formed for finer particles. Therefore, the packs of the ring essentially serve as a base on which the true filter medium is admitted.

Stacked-disc filters are also designed which is a very robust device. It consists of several rings which are assembled on a grooved rod. The assembled stacks are placed in a pressure vessel which can be sterilized if necessary. During use, the filtrate passes between the discs and is removed through the grooves. Solids are deposited on the filter coating. Operation is continued until the resistance becomes too high. The solids are removed from the rings by applying back pressure via the fluted rods. There is no filter cloth and the bed is easily replaced, labor costs are low.

Advantages of Meta Filters

- It can be used at high strength and pressure with no danger of bursting the filter medium.

- It is an economical filter. As there is no filter medium as such, the running cost is low.

- It can be made of non-corrosive material and avoid contamination with the most sensitive product.

- By selecting the appropriate material to form the filter bed, it is possible to filter very fine particles. Removal of the cake is effected effectively by backflushing with water, further cleaning is necessary.

Uses

- These filters are used for clarification and polishing of beverages and pharmaceutical suspension having low solid content.

- Suitable for viscous liquids

- Suitable for corrosive substances.

- It is used in the clarification of syrups, and products such as insulin liquors.

Make sure you also check our other amazing Article on : Factors Influencing Filtration