Principle

Table of Contents

Planetary Mixers work on the principle of shear that develops between the stationary wall and the rotating blade. The blade is also used to reduce the size. The planetary blades rotate on their axis while they travel around the center of the mixing bowl which ensures complete and effective mixing.

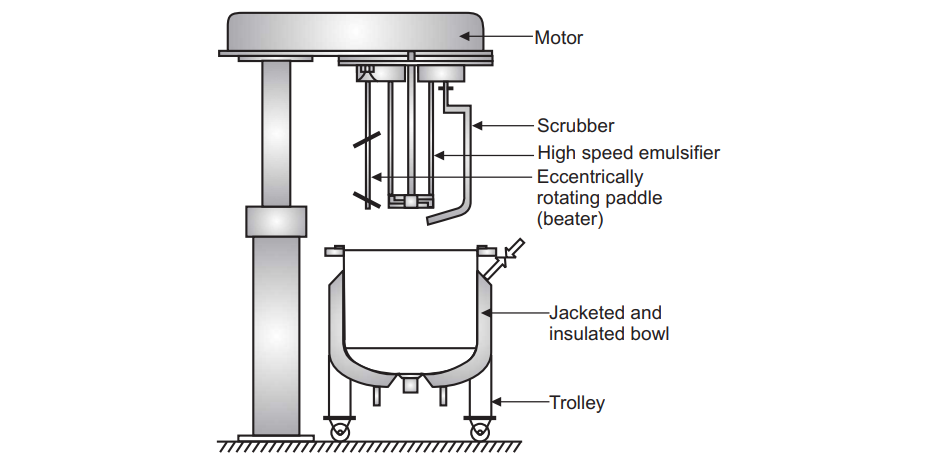

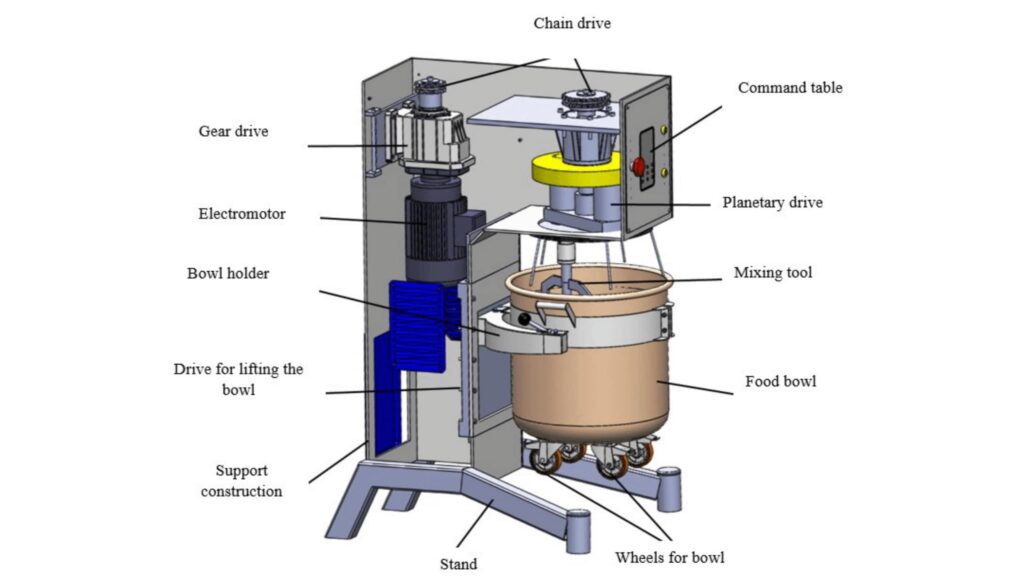

Construction of Planetary Mixers

It consists of a vertical cylindrical shell or bowl that can be removed. The shell or bowl is covered and may be provided with nozzles, a liquid spray arrangement viewing ports. The material can be loaded into the mixer either through the nozzles on the top cover, or directly loaded into the mixer bowl. The mixer has two blades that rotate on their axes when they orbit the mixing container on a common axis. The mixing Blade is mounted at the top of the shell. The drive system consists of a motor and a gearbox that drives the planetary head. Each planetary blade is generally driven by gears that rotate due to the movement of the planetary head.

Working of Planetary Mixers

The material to be mixed is loaded into a mixing bowl or shell. The blades rotate on their axis when they orbit the mixing bowl on a common axis. Therefore there is no dead spot in the mixing and high shear is applied for mixing. After mixing, the material is discharged through a bottom valve, or by manual scooping of the material from the bowl.

Advantages of Planetary Mixers

- Simple construction, operation, and relatively lower cost

- No dead spot in the mixing

- The rotation speed of blades can be varied

- Used for the wet granulation process

- High mixing efficiency

Disadvantage

- Require high power

- Heat build-up within powder mix

Make sure you also check our other amazing Article on : Construction And Working Sigma Blade Mixer