Spoilage is the term that indicates goods that do not meet production standards. It is the method by which material or the amount of material is wasted or scrapped during the manufacturing process. In another word, it is a form of substandard drug or food in which the quality or value, or usefulness of the article is destroyed or impaired by the action of microorganisms like fungi or bacteria to render the article unfit for human consumption. Hence, spoilage is a complex reaction in which a combination of microbial and biochemical activities are interacting. Legally they are known as spoilage. These substandard drugs when proceeding further to be saleable as goods units are known as defectives. Examples: Rancid meat, sour milk, moldy cheese, etc. The spoilage is mainly determined based on microbial colonization form which depends on the characteristics of products, method of processing, and the storage condition. These factors are characterized into four types viz. intrinsic parameters (physical, chemical, structural properties of foods, water activity, acidity, redox potential), extrinsic parameters (temperature, humidity, atmosphere conditions), modes of preservation and processing (physical and chemical treatments, change characteristics of food products, determination of microbial flora in food products) and implicit parameters (microbial interferences either by synergistic or antagonistic action, destruction of one organism by another species).

Types of Spoilage:

Table of Contents

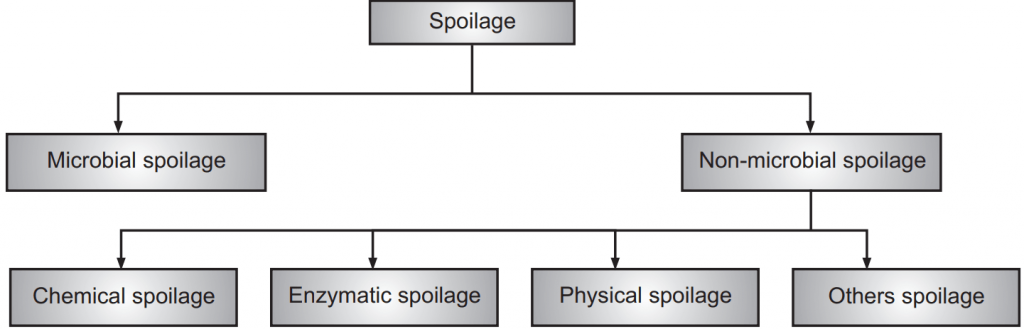

Spoilages are mainly two types.

(A) Microbial spoilage and

(B) Non-microbial spoilage.

Microbial Spoilage:

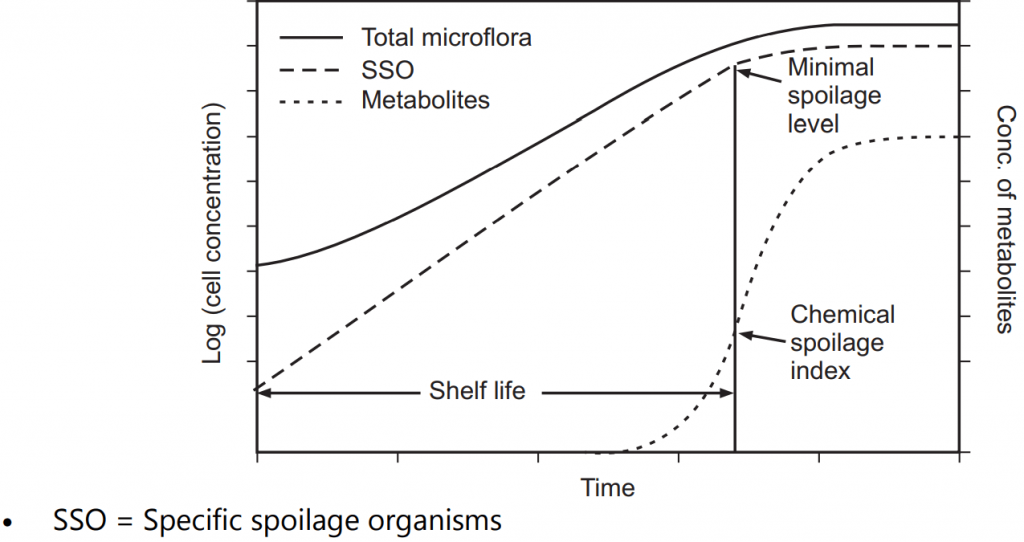

It includes the contamination of Pharmaceutical products with the microbes that lead to spoilage of the product. It affects drug safety and quality and is not intended for use. Hence, microbial spoilage is the deterioration of pharmaceutical products by the contaminant microbes such as bacteria, molds, fungi, and yeasts. The growth pattern of microbial spoilage is shown in Fig.1.

Non-Microbial Spoilage:

These are the chemical reactions caused by foreign material in the foodstuff or by enzymes that occur in the foodstuff naturally resulting in rancidity, staling, discoloration, drying out, or damaged by an insect.

Chemical spoilage:

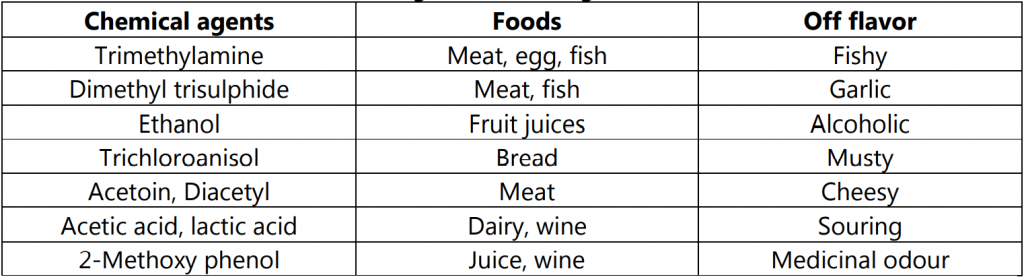

It is based on a non-enzymatic chemical reaction that occurred within the foods and resulted in a change in flavor. Some examples are given in Table.1.

Enzymatic spoilage:

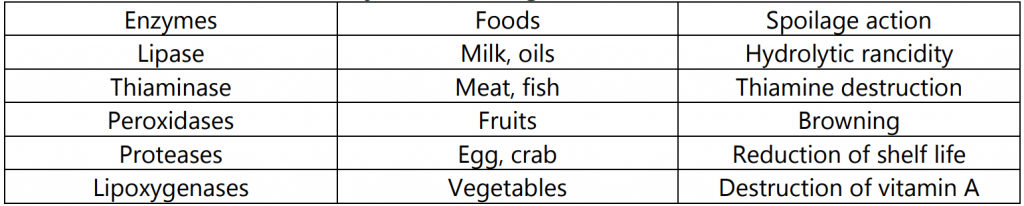

It is based on enzymatic reactions that occurred in foods and changes in chemical nature and resulted in rancidity. This rancidity occurred by two types of chemical reactions viz. hydrolytic and oxidative rancidity. For example, Triglyceride upon hydrolytic reaction in presence of lipase enzyme forms glycerol and free fatty acid. Further, Linolenic acid with various oxidative reactions forms 3-(E)-hexenal and 12-oxo-9 (Z) dodecenoic acid with the help of lipoxygenase and hydroperoxide lyase. Some examples are given in Table.2.

Physical spoilage:

It occurs due to temperature, light, relative humidity, and mechanical damage of the food components. For example Oxidation of food occurs due to light and changes in color, flavor, and chemical nature, like the greening of potatoes, sunlight flavor in milk, loss of vitamin D, E, etc.

Other spoilage:

It occurs due to insects, rodents, birds, and other animals and results in changes in color, odor, and chemical nature.

Based on the rate of spoilage, they are classified into three types like high perishable, semi-perishable, and stable or non-perishable spoilage.

(i) High perishable: Meat, fish, poultry, eggs, milk, fruits, and vegetables, etc.

(ii) Semi-perishable: Potatoes, some apple varieties, nutmeats, etc.

(iii) Stable or non-perishable: Sugar, flour, dry beans, etc.

- Spoilage of fruits and vegetables: Acid-tolerant bacteria are responsible for the spoilage of fruits and vegetables such as Lactobacillus species. Not only deterioration is also caused by animals and birds, but wounding, cutting, freezing, environmental conditions, contact with spoiled foods, etc. also causes food spoilage. Mainly two types of spoilages are observed likely bacterial soft rot and rhizopus soft rot.

Bacterial soft rot is caused by Erwinia carotovora, ferment pectins, Pseudomonas marginalis, etc. Bacillus and Clostridium are causes for water-soaked appearance and bad odor of vegetables, black mold rot causes spotting of leaves and fruits. Rhizopus soft rot is caused by Rhizopus. Cottony growth of mold forms black spots of sporangia covering the foods. Alternaria rot is caused by Alternaria tenuis, resulting in green-brown spots. Rots of juicy fruits result in leakage.

- Spoilage of cereals: Moisture content above 12 to 13 percent causes spoilage of cereals due to the growth of molds, bacteria, and yeasts. Molds are grown in little moisture whereas in high moisture condition yeasts and bacteria grows. Aspergillus, Penicillium, Mucor, Rhizopus, Fusarium are some common molds that produce mycotoxins. Acetobacter spp., tactics and Coliforms, Micrococci, and Bacillus are some species causing spoilage of cereals.

- Spoilage of milk: Souring of milk is caused by Streptococcus lactis, Enterococci, Lactobacilli, etc. Proteolysis causes a bitter taste of milk which is caused by Bacillus, Serratia, Pseudomonas, etc.

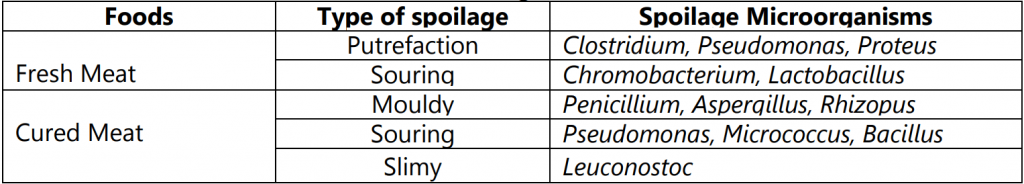

- Spoilage of meat: Raw meat is spoiled by microbial as well as enzymatic action. Excessive autolysis causes souring of meat.

- Spoilage of fish: Fish is spoiled by autolysis, oxidation, or by bacterial activity. Under anaerobic conditions, the surface slime of fishes is caused by Pseudomonas, Streptococcus, Micrococci, etc. Surface color changes due to pigmentation. For example, Red spot is caused by Serratia marcescens, Pseudomonas gives blue color.

- Spoilage of eggs: Spoilage of eggs is promoted by cracking, improper washing, and storage. Egg yolk is a good growth medium for microorganisms due to its high nutrient. Molds that cause the spoilage of eggs are Penicillium, Mucor, Sporotrichum, etc. Spoilage of eggs is also occurred by fungi. There are two stages of egg spoilage like pin spot molding and fungal rotting.

- Spoilage of canned foods: Canned foods are chemically spoiled due to hydrogen swells as a result discoloration of inside the can, cloudiness of liquors, and that affect the nutritive value of the canned foods. Due to bacterial spoilage loss of nutritive value occurs by thermophilic and mesophilic bacteria. Thermophilic anaerobes form acid and gas whereas sulfide spoilage occurs by Desulfotomaculum significantly that resulted in black colonies. Sometimes ends can flatten due to souring caused by Bacillus stearothermophilus.

Some of the important food spoilages along with their causative microorganisms are tabulated in Table.3.

Factors Affecting Microbial Spoilage:

Pharmaceutical products contain a wide range of excipients in addition to active pharmaceutical ingredients for making the formula easy to manufacture, stable, effective, and convenient to the patient. These products in the pharmaceutical industry must meet high microbiological specs. If they are not sterile, they should have not more than a minimal microbial population at the time of product release and afterward. If there is microbial spoilage of products then products are unsuitable for use, resulting in financial problems to the manufacturers and also a potential health hazard to the patients. Hence microbial spoilage is required to be minimized which depends on many factors that are enlisted as:

- Types and size of contaminant inoculum.

- Nutritional factors.

- Water.

- Storage temperature.

- pH.

- Oxidation-reduction balance (Redox potential).

- Package design.

Types and Size of Contaminant Inoculum

Very low levels of contaminants that are unable to replicate in a product might not cause appreciable spoilage but, if a higher contaminant bio-burden occurs, the built-in protection could be insufficient and spoilage occurs.

This higher contamination arises if:

1. Raw materials were unusually contaminated;

2. A problem of the plant-cleaning protocol occurs;

3. Biofilm detached itself from within supplying pipework;

4. There was demolition or maintenance work in the vicinity of the manufacturing site

5. Misuse of the product occurring during administration.

Nutritional Factors

Many spoilage microorganisms have simple nutritional requirements and metabolic adaptability, enabling them to utilize many formulation components as substrates for biosynthesis, growth, and trace materials contained in them. The use of animal products and crude vegetable materials in a formulation provides an additionally nutritious environment. Demineralized water prepared by ion-exchange methods, contains sufficient nutrients to allow significant growth of many water-borne Gram-negative bacteria like Pseudomonas spp.

Water

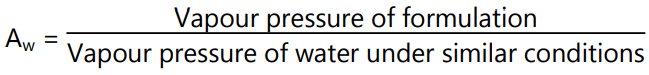

It is the most important cause of the survival and growth of micro-organisms. Some solute-rich medicines such as syrups appear to be ‘wet’, microbial growth in them may be difficult since the microbes have to compete for water molecules with the large numbers of sugar and other molecules of the formulation which also interact with water via hydrogen bonding. An estimate of the proportion of the non-complexed water in a formulation available to equilibrate with any microbial contaminants and facilitate growth can be obtained by measuring its water activity (Aw).

The greater the solute concentration, the lower is the water activity. Most microorganisms grow best in dilute solutions (high Aw) and, as solute concentration rises (lowering Aw), growth rates decline until a minimal, growth-inhibitory Aw is reached. The Aw of aqueous formulations is lowered to increase resistance to microbial attack by the addition of high concentrations of sugars or polyethylene glycols. Condensed water films are accumulated on the surface of ‘dry’ products such as tablets or bulk oils following storage in damp atmospheres with fluctuating temperatures, resulting in high localized Aw to initiate fungal growth.

Storage Temperature

The actual storage temperature determines the spoilage by particular types of microorganisms. Spoilage of pharmaceuticals occurs potentially over the range of about 20°C to 60°C. Storage in a deep freeze at −20°C or lower is used for long-term storage of foodstuffs and some pharmaceutical raw materials and dispensed total parenteral nutrition feeds are stored in hospitals for short periods at −20°C to even further minimize the risk of growth of any contaminants that are introduced during their aseptic compounding. Reconstituted suspensions and multi-dose eye drop packs are sometimes dispensed with the instruction to ‘store in a cool place’ such as a domestic fridge (8°-12°C), or “store in the refrigerator “ partly to reduce the risk of in-use contamination growing before the expiry date. Water for Injections is recommended to be held at 80°C or above after distillation and before packing and sterilization to prevent possible regrowth of Gram-negative bacteria, and the release of endotoxins.

pH

Extremes of pH prevent the microbial attack. They grow at neutral pH, therefore acidic or alkaline formulations are less susceptible to spoilage. Around neutrality, bacterial spoilage is more likely, with reports of pseudomonas and related Gram-negative bacteria growing in antacid mixtures, flavored mouthwashes, and in distilled or demineralized water. Above pH 8, spoilage is rare for soap-based emulsions. Products with low pH levels such as fruit juice-flavored syrups are attacked by mold or yeast. Yeasts are metabolized of organic acids and raise the pH to levels where secondary bacterial growth occurs. In the food industry, low pH adjustment is made to preserve foodstuffs only.

Redox Potential

The ability of microbes to grow in an environment is influenced by its oxidation-reduction balance since they require compatible terminal electron acceptors to permit the function of their respiratory pathways. The redox potential in the viscous emulsion is high due to the high solubility of oxygen in most fats and oils.

Packaging Design

It has a major influence on the microbial stability of some formulations in controlling the access of contaminants during both storage and use. The most important dosage form such as parenteral drugs is protected because of the high risks of infection by this route. Self-sealing rubber closures are used to prevent microbial entry into multi-dose injection containers following withdrawals with a hypodermic needle. Wide-mouthed cream jars are replaced with narrow nozzle and flexible screw-capped tubes to remove the likelihood of operator-introduced contamination during use. For medicines that rely on their low Aw to prevent spoilage, packaging such as strip foils is must be of water vapor-proof materials with fully efficient seals. Sacking, cardboard, card liners, corks, and paper are unsuitable for packaging pharmaceuticals because they are heavily contaminated with bacterial or fungal spores. These are replaced by non-biodegradable plastic materials. In the past, packaging in hospitals is frequently re-used for economic reasons.

Other factors affecting microbial spoilage of pharmaceutical products include:

- Relative Humidity

- Oxygen Availability

- Osmotic Pressure

- Surface Tension

Make sure you also check our other amazing Article on : Standardization of Vitamins