Principle of Silverson Mixer Emulsifier

Table of Contents

Silverson mixer emulsifier produces intense shearing force and turbulence by the use of high-speed rotors. This turbulence causes the liquids to pass through fine interstices formed by closely placed perforated metal sheets. Circulation of material takes place through the head by the suction produced in the inlet at the bottom of the head. Circulation of the material ensures the rapid breakdown of the dispersed liquid into smaller globules.

Construction of Silverson Mixer Emulsifier

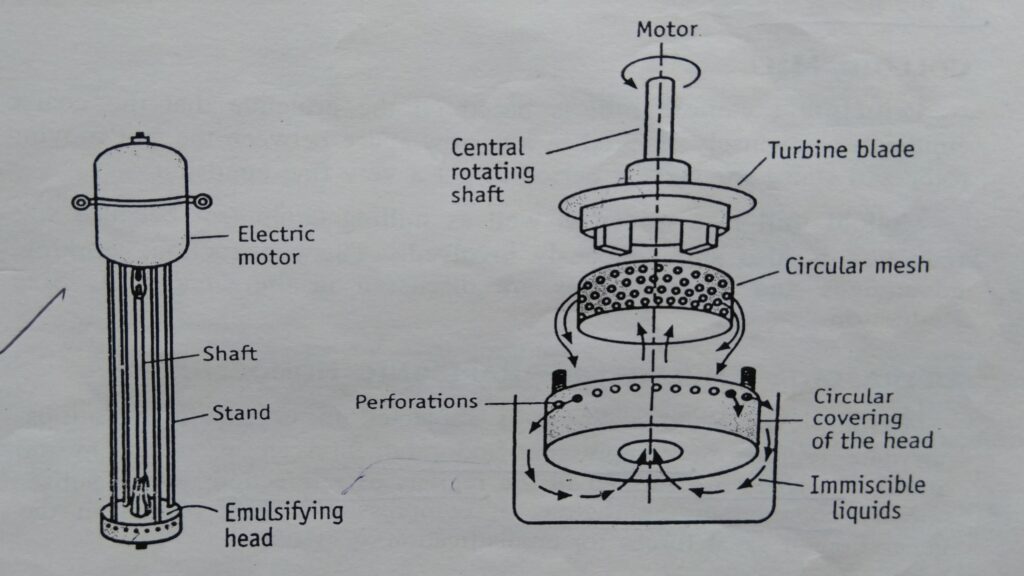

The construction of a Silverson emulsifier is shown in the Figure. It consists of long supporting columns connected to a motor that gives support to the head. The central portion contains a shaft, one end of which is connected to the motor and the other end is connected to the head. The head carries turbine blades. The blades are surrounded by a mesh, which is further enclosed by a cover having openings.

Working of Silverson Mixer Emulsifier

The emulsifier head is placed in the vessel containing immiscible liquids (or coarse emulsion) in such a way that it should get completely dipped in the liquid. When the motor is started, the central rotating shaft rotates the head, which in turn rotates turbine blades at a very high speed. This creates a pressure difference. As a result, liquids are sucked into the head from the center of the base and subjected to intense mixing action. Centrifugal forces expel the contents of the head with great force through the mesh and onto the cover (Figure). As a result, a fine emulsion emerges through the openings of the outer cover. The intake and expulsion of the mixture set up a pattern of circulation to ensure the rapid breakdown of the bigger globules into smaller globules.

Uses: Silverson mixer is used for the preparation of emulsions and creams of fine particle size.

Advantages

- Silverson mixer is available in different sizes to handle liquids ranging from a few milliliters to several thousand liters.

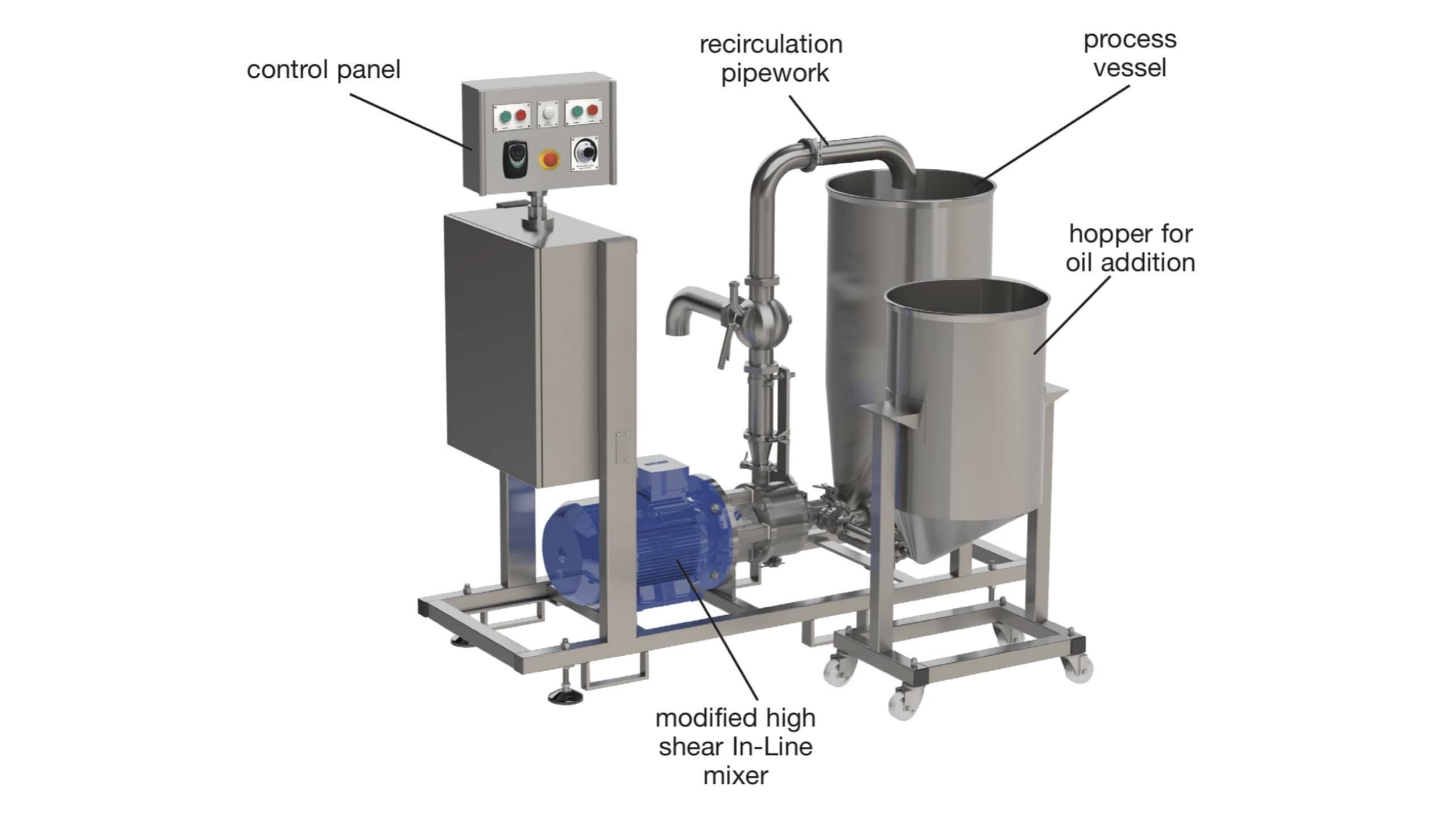

- It can be used for batch operations. It is also used for continuous operation by incorporating into a pipeline, through which the immiscible liquids flow.

Disadvantage

- Occasionally, there is a chance of clogging of the pores of the mesh.

Make sure you also check our other amazing Article on : Mechanisms of Liquid Mixing