Principle

Table of Contents

Steam is supplied to a jacketed kettle (evaporating pan) in which aqueous extract is placed. Steam gives out heat to the kettle. The heat is transferred to the aqueous extract by conduction and convection. The temperature raises and the escaping tendency of the solvent molecules into vapor increases. Stirring further enhances the vaporization of solvent molecules.

Construction of Steam Jacketed Kettle

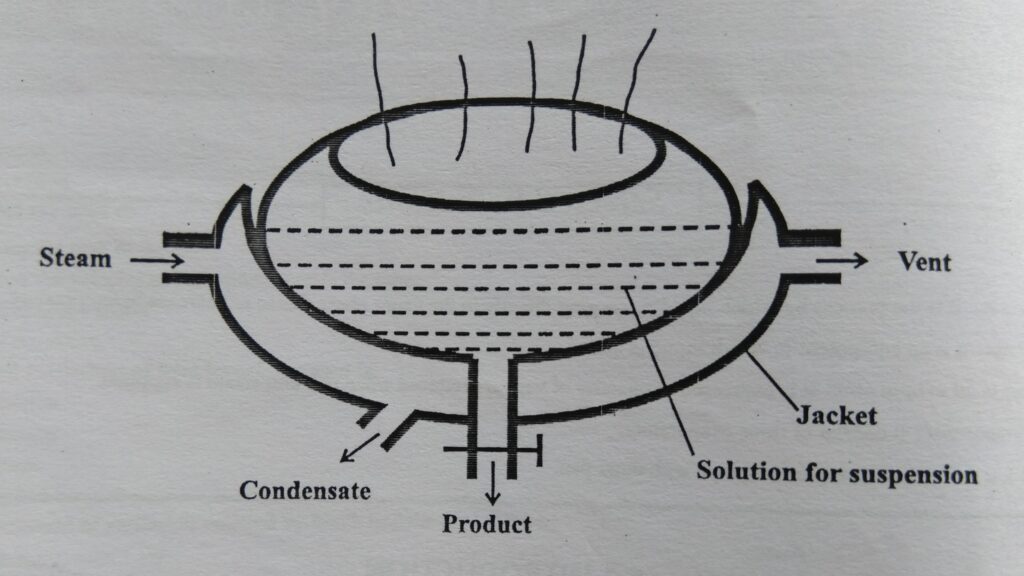

The construction of a steam jacketed kettle is shown in Figure. It is a hemispherical structure consisting of an inner pan called a kettle. It is enveloped with an outer pan called a jacket. The two pans are joined to enclose a space through which steam is passed. For smaller quantities, the kettle is made up of a single sheet of metal. For larger capacities, several sheets are welded. Though several metals are used as a material of construction, for practical purposes the following is used. Copper is an excellent material for the kettle, because of its good conductivity. If acidic materials are evaporated, some quantity of copper would dissolve. For such preparations, tinned copper is used. Iron is used for the construction of the jacket because it has minimum conductivity. To prevent rusting of the jacket, the iron is either tinned or enameled on the inner surface.

An inlet for the steam and an outlet (vent) for noncondensed gases are provided near the top of the jacket. Condensate leaves the jacket through the outlet provided at the bottom. The kettle is provided with one outlet for product discharge at its bottom.

Working of Steam Jacketed Kettle

Aqueous extract to be evaporated is placed in the kettle. Steam is supplied through the inlet. Steam gives out its heat to the contents and condensates leaves through the outlet. The contents must be stirred manually for smaller volumes and mechanically for larger volumes. The mechanical stirrer is not shown in Figure. The rate of evaporation is fast in the initial stages and decreases gradually as the liquid gets concentrated.

Any room where evaporation is carried by this apparatus must have good ventilation to remove the vapor. Otherwise, the room is quickly filled with a dense fog of condensed vapor and waterfalls from the roof and runs down the walls. Fans fitted over the pan not only remove the vapor and prevent condensation in the room but also accelerate the rate of evaporation by quickly removing saturated air from the surface of the liquid.

The kettle may be fixed or made to tilt. A kettle of capacity up to about 90 liters may be made to tilt. But above this capacity, the weight of the pan along with its contents becomes too great to tilt. Hence, the bottom outlet is used to collect the concentrated product.

Uses: Evaporating pan is suitable for concentrating aqueous and thermostable liquors, for example, liquorice extract.

Advantages

- Evaporating pan is constructed both for small-scale and large-scale operations.

- It is simple in construction and easy to operate, clean, and maintains.

- Its cost of installation and maintenance is low.

- A wide variety of materials can be used for construction such as copper, stainless steel, and aluminum.

- Stirring of the contents and removal of the product is easy.

Disadvantages

- In evaporating pans, the heat economy is less. Hence. cost per unit material production is more.

- It is not suitable for heat-sensitive materials due to a long time of exposure.

- The heating area decreases as the product gets more concentrated.

- As it is an open type, the vapor passes into the atmosphere, which can lead to saturation of the atmosphere, slowing evaporation as well as causing discomfort.

- The boiling point of water cannot be reduced, since reduced pressure can not be created in an open type of evaporator.

Make sure you also check our other amazing Article on : Factors Influencing Evaporation